- 10,350

- 77

- 48

- Location

- Meadows of Dan, Virginia

Kerosene is harder to start.

Steel Soldiers now has a few new forums, read more about it at: New Munitions Forums!

HmmI have this image of coming in the house with no eyebrows.

A 2-minute start attempt is not long enough! Try 3 to 5 minutes, just don't quit.So I have new updates. The heater will not light off, and I have fuel flowing out of the regulator block, but it is not flowing out of the exhaust, even after several attempts of 2 minute start attempts each. I need to pull the copper injection tube and the glow plug assembly....

Thanks everybody for sticking with me. Not that it matters, but I don't think "Hi" is locked out during a start. The fuel solenoid clicks twice as fast on Hi as it does "Lo", even during a start attempt. I am keying into this because maybe it is an indicator that something else is still wrong? Also looks like my igniter is getting about 12V during usage.A 2-minute start attempt is not long enough! Try 3 to 5 minutes, just don't quit.

Keep in mind that all the while, fuel is dripping into the combustion chamber and accumulating. After several aborted starts, you will have a fire hazard with fuel sloshing around in the heater.

In the beginning (5 or 6 years ago), I would siphon out the fuel after failed starts. In military service, you'd return the heater to maintenance for this procedure.

The "HI" is locked out during the start sequence, so don't worry about the hi and lo switch at this time.

The fuel flow, or drip, from the fuel control valve is critical during the start period and the valve must be calibrated exactly as specified in the TM. A soaked wick may not help.

The igniter is designed for about 6 volts and is connected via a large resistor (to last longer), in case you decide to test it.

The fuel is also important, #1 diesel (Winter diesel) probably best, but I have never tried gasoline. Don't even think about using waste motor oil or biodiesel/veggie oils.

To make sure my fuel supply is not a concern, I have a dedicated jerry can with good fuel on my truck and my heater seems very happy.

View attachment 537113

Good to know. I used kerosene with the unit in the back of my M109 and Iwondering if that is part of the reason that does not want to start. I noticed diesel works better for the manifold flame heater on my deuce. I have a separate tank for my manifold flame heater since I use WMO for engine fuel. Thank you for the confirmation, it helps. I guess I should switch fuels. I know they were designed for diesel but I was thinking kerosene was more pure/better for the wicks. I had wick issues so thats why i went with kerosene. Good to know.Kerosene is harder to start.

74M35A2 has the heater switch box on the right.The blower runs at a lower speed during start (lower than in "LO").

Which control box do you have? The push to test light is supposed to confirm that you have 24vdc to the unit and turns on after the unit start up.

Is it one of these?

View attachment 537126

After the unit has shut down (switched to "OFF"), there is a purge time, that could last 1 to 2 minutes as remaining fuel burns up after fuel pump is shut off...

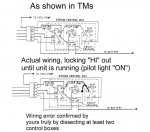

Okay, then the wiring diagram is as shown here, with and without correction by yours truly.74M35A2 has the heater switch box on the right.

I think his light assembly is corroded some or something.... it does not want to push in when it says on the front, "push to test". We tested the bulb and it tests good and worked for him in the past. Everything else in the control box looks healthy and no signs of corrosion.

The flame switch adjustment is important and if the heater shuts down after, say 10 to 20 seconds, then you may want to turn the screw an additional 1/4 turn or so, which will require the temperature to be slightly higher before the "switch-over".Thanks. 10-4 on the blower running at a reduced rate, and also the purge run after flame is out. Both of those are working correctly, and yesterday I adjusted the flame switch to insure it, prior to testing (1/2 turn CW after click when cold).

So is the error a mistake in just the TM, or are control heads wired incorrectly? I have the control head on the right of your picture.

Pretty sure I am just down to a fuel volume delivery issue. Everything else seems in check (besides the push-to-test light, but I think I just read the box requires grounding for that to work, and now confirmed that via your schematic).

We get it, advertisements are annoying!

Sure, ad-blocking software does a great job at blocking ads, but it also blocks useful features of our website like our supporting vendors. Their ads help keep Steel Soldiers going. Please consider disabling your ad blockers for the site. Thanks!