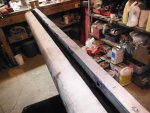

Your work on the tailgate is coming along nicely.

You might be on to something, starting a side gig rebuilding M1009 gates.

It scares me to think that when I started to play around with K5 Blazers in the early 90's factory GM gates were $98 at my local Chevy dealer.

Looking back I wished I saved some of the ones I scraped. That won't happen again.

Thanks.

You might be on to something, starting a side gig rebuilding M1009 gates.

It scares me to think that when I started to play around with K5 Blazers in the early 90's factory GM gates were $98 at my local Chevy dealer.

Looking back I wished I saved some of the ones I scraped. That won't happen again.

Thanks.