Flea

Member

- 457

- 10

- 18

- Location

- Northeast TN

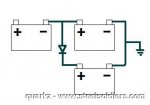

What about using a speed controller from a golf cart? Theoretically speaking, you could use one designed for 24 volts and be able to get anywhere from 0-24 volts out of the controller. With ratings in the hundreds of amps, power supply wouldn't be a problem.

The downside is you would have to use a multimeter to get the exact voltage you need dialed in. Each time you wanted to change voltage, you would have to break out the multimeter and repeat the whole process...

I think this could be a workable solution to 12 volts, perhaps voltage could even be dialed up to charge a third battery without having to resort to adding a separate 12 volt alternator?

Thoughts?

The downside is you would have to use a multimeter to get the exact voltage you need dialed in. Each time you wanted to change voltage, you would have to break out the multimeter and repeat the whole process...

I think this could be a workable solution to 12 volts, perhaps voltage could even be dialed up to charge a third battery without having to resort to adding a separate 12 volt alternator?

Thoughts?