K9keeper

New member

- 8

- 3

- 3

- Location

- Riverside/CA

Hi,

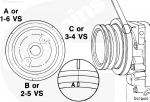

I'm new here so I hope this post is in the right place. We're in the process of getting a 1982 5 Ton Military truck back on the road. It is powered with the Cummins NHC250. In preparation for performing the overhead adjustments, we have noted the absence of a pointer anywhere on the front cover used for indexing the 1-6, 5-2

and 3-4 marks on the accessory drive pulley. Although this truck is a 1982 model the I.D. plate on the engine shows a build date of "10-71". Could this earlier engine of had a bolt-on type pointer that has been omitted? There is a flat machined pad with a threaded hole located where the pointer should be. The pad faces the front of the engine. I've cleaned the area quite well but have found nothing resembling a pointer. I believe the pulley is marked with a #1TC position that I could use as a reference point and fabricate a pointer to install. We are pulling the injectors out for testing anyway so a dial indicator on #1 piston will find TDC.

Has anyone run into this before? The accessory drive pulley appears to have the necessary markings on it but no pointer to be found.

Thanks for your consideration in this matter.

I'm new here so I hope this post is in the right place. We're in the process of getting a 1982 5 Ton Military truck back on the road. It is powered with the Cummins NHC250. In preparation for performing the overhead adjustments, we have noted the absence of a pointer anywhere on the front cover used for indexing the 1-6, 5-2

and 3-4 marks on the accessory drive pulley. Although this truck is a 1982 model the I.D. plate on the engine shows a build date of "10-71". Could this earlier engine of had a bolt-on type pointer that has been omitted? There is a flat machined pad with a threaded hole located where the pointer should be. The pad faces the front of the engine. I've cleaned the area quite well but have found nothing resembling a pointer. I believe the pulley is marked with a #1TC position that I could use as a reference point and fabricate a pointer to install. We are pulling the injectors out for testing anyway so a dial indicator on #1 piston will find TDC.

Has anyone run into this before? The accessory drive pulley appears to have the necessary markings on it but no pointer to be found.

Thanks for your consideration in this matter.