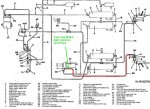

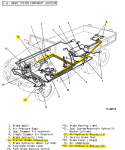

Here is the air line diagram:

View attachment 804931

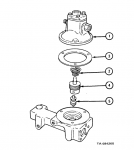

So, what you are asking is "is the piston (4 and control valve piston 5) inside the compensator mounted to the airpack actuated by hydraulic pressure, air pressure or mechanically"?

View attachment 804936

Based on the assembly instructions, the control piston (5) protrudes into the bore of the slave cylinder. That would suggest that it is being activated by hydraulic pressure.

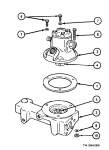

View attachment 804937

From rebuilding my air pack I do not remember the hydrualic piston inside the slave cylinder being anything but cylindrical; there was no step or wedge shape that I recall that would mechanically lift the control piston.

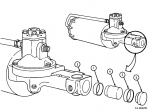

View attachment 804938

The assembly diagram seems to support that there is no mechanical connection to the control piston.

I would suggest that you are indeed correct and total failure of the hydraulic side of the brake system will also fail the trailer service line. The thinking error that made all of this much more complicated of a post than it needs to be is the simple fact that it is the action of the hydraulic MC that activates the air hydraulic brake booster (aka airpack).

Hydraulic fluid loss - no master cylinder function. No master cylinder function - no air pack function. No air pack function - no service air line function.

MSeriesRebuild explained the air assisted hydraulic brakes back in 2008:

"Well nobody covered exactly how the system functions in detail. When the pedal is applied, fluid pressure travels from the M/C to the booster. This activates the diapram in the hydraulic portion of the booster. When the diaphram opens the airway allowing compressed air from the storage tanks to flow, the piston inside the large barrel portion of the booster assembly is forced into motion by air pressure. An atmospheric line on the opposite side of the piston allows air on that side of the piston to escape. The air operated piston is forcing hydraulic or brake fluid out to the wheel cylinders, this applies the brakes. When the pedal is released, the hydraulic diaphram is closed by spring pressure, the line on the atmospheric side allows air from outside to flow in so the piston can return to the neutral position via spring pressure. Fluid flows backwards toward the M/C allowing brakes to release. The atmospheric line is plumbed into the air cleaner system on M35A2 trucks so the system draws & expels clean air. That's about as simple as I can explain it. "