SteveKuhn

New member

- 1,227

- 4

- 0

- Location

- Hasbrouck Heights NJ

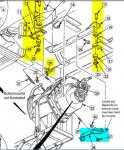

Questions 1st, explanation 2nd; TM highlighted below. I don't think this duplicates another thread.

- Does anyone know a NAPA or other civilian part # for transfer case bushings/mounts (12 & 19 in the TM)?

- Is there anything special about the bolts, nuts, and washers that go with them? I'd like to replace them, too.

I've already started contacting the usual vendors for pricing and availability for the above.

- Any experience with pop-outs in high range when 12 & 19 are hard and compressed that was fixed when they were replaced?

- Other comments?

On Memorial Day, my transfer case began to pop out of high range, particularly on shifts to/from 2nd <-> 4th. The lever had always waved back to front a few inches under pressure.

I read all of the threads on transfer cases about worn internals and other possible causes. Last fall, about 600 miles ago, there were only moderate filings on the plug when I changed the gear oil. Dirty but unburned.

I bought a Rockwell-rebuilt case and picked it up at COMVEC. Don't regret that so far. I've done about 150 or so miles with the lever bungeed - no pop-outs.

In preparation for installation, we went over the truck in detail yesterday, trying to anticipate what to have on hand. We found that most of the mounts were loose and that we couldn't really torque down nuts 12 & 19 in the TM because the rubber bushings/mounts are compressed and hard.

We torqued everything to spec as best we could and in 25 mins of local traffic driving afterward with lots of shifts up and down, it only popped 3x (95%+ improvement.) The transmission grinding that I feared was either that going too or me losing my touch disappeared and shifts were clean and solid.

My decision now is whether to replace those mounts and leave the old transfer case in place, hoping that new mounts will eliminate the pop outs, or just swap it and get it over with. Maybe sell the old one if we can check it on the bench and determine that it's OK.

If I was set up better and a better wrencher, it wouldn't be a decision - I'd do the mounts only 1st. However, I need to have either job done and mounts-only is going to cost a considerable portion of what the swap does in labor. Course, then I'd have a top notch transfer case either in reserve or for sale.

Comments and part numbers welcome.

Thanks.

Steve

- Does anyone know a NAPA or other civilian part # for transfer case bushings/mounts (12 & 19 in the TM)?

- Is there anything special about the bolts, nuts, and washers that go with them? I'd like to replace them, too.

I've already started contacting the usual vendors for pricing and availability for the above.

- Any experience with pop-outs in high range when 12 & 19 are hard and compressed that was fixed when they were replaced?

- Other comments?

On Memorial Day, my transfer case began to pop out of high range, particularly on shifts to/from 2nd <-> 4th. The lever had always waved back to front a few inches under pressure.

I read all of the threads on transfer cases about worn internals and other possible causes. Last fall, about 600 miles ago, there were only moderate filings on the plug when I changed the gear oil. Dirty but unburned.

I bought a Rockwell-rebuilt case and picked it up at COMVEC. Don't regret that so far. I've done about 150 or so miles with the lever bungeed - no pop-outs.

In preparation for installation, we went over the truck in detail yesterday, trying to anticipate what to have on hand. We found that most of the mounts were loose and that we couldn't really torque down nuts 12 & 19 in the TM because the rubber bushings/mounts are compressed and hard.

We torqued everything to spec as best we could and in 25 mins of local traffic driving afterward with lots of shifts up and down, it only popped 3x (95%+ improvement.) The transmission grinding that I feared was either that going too or me losing my touch disappeared and shifts were clean and solid.

My decision now is whether to replace those mounts and leave the old transfer case in place, hoping that new mounts will eliminate the pop outs, or just swap it and get it over with. Maybe sell the old one if we can check it on the bench and determine that it's OK.

If I was set up better and a better wrencher, it wouldn't be a decision - I'd do the mounts only 1st. However, I need to have either job done and mounts-only is going to cost a considerable portion of what the swap does in labor. Course, then I'd have a top notch transfer case either in reserve or for sale.

Comments and part numbers welcome.

Thanks.

Steve

Attachments

-

96 KB Views: 92