- 1,079

- 2,072

- 113

- Location

- Wauchula, FL

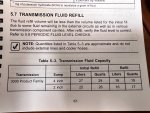

For reference I just changed my old ATF fluid and filters. It’s been about 8 years and 30,000 miles on that fluid and filter. And the fluid and filters were super clean, barely anything on the drain plug magnets and like mentioned earlier only the finest of particles could be seen in just the right light. Compared to the axle drain plug magnets the transmission was spotless.

Installed Transynd 668. It has drain intervals of 300,000 miles in general duty and 150,000 in server duty transmissions.

Installed Transynd 668. It has drain intervals of 300,000 miles in general duty and 150,000 in server duty transmissions.