- 875

- 677

- 93

- Location

- Cooperstown NY

No need to cut your wiring. GM had an issue with a batch of some bad relays years ago and have since fixed the issue. Just keep your batteries charged and your truck maintained for quick starting like originally designed and you'll be fine. Pop in a new GM unit just for good measure?Good thing I asked you about that before installing it. I noticed all the hype about it is from around 10 years ago and wasn’t sure if it was still recommended. I’d rather not cut my wiring but I wouldn’t mind if it meant the truck would benefit from it. Should I pop in a new GM unit just for good measure?

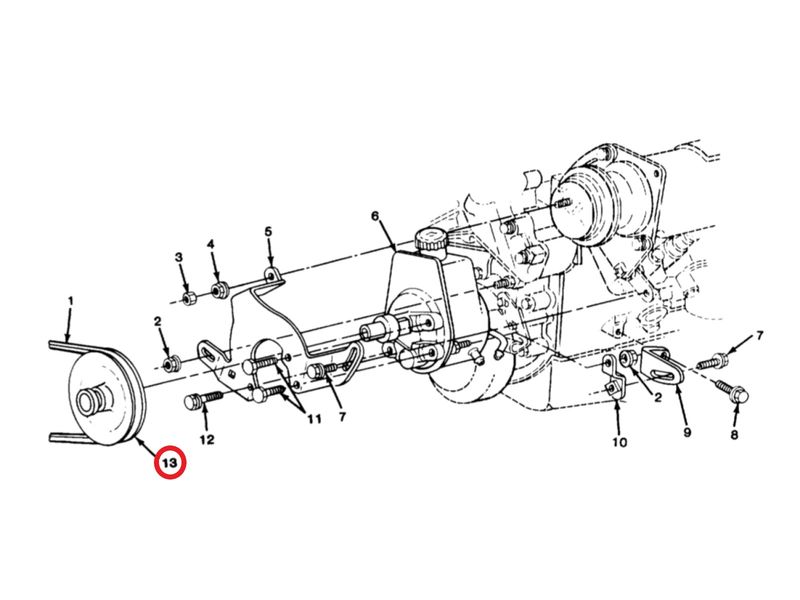

As far as the power steering bracket goes, I believe it is all in tact except for that tab on the top left. It was being held on by the nut and I still have the piece.

View attachment 839482