Ok, so I told peashooter I'd post some updates once I was done with mine.

Long post so take your ritalin.

I wanted to use the armor headlights (

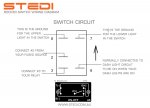

http://www.steelsoldiers.com/showthread.php?23925-Headlights-or-spotlights) for the reverse lights, as they are strong, military, have a lot of light output, etc. Once I saw gringeltaube's switch, I had an idea. Use the transmission switch for the high beam, since you figure you want the maximum light output for safety (letting others know the truck is reversing) and for seeing in the dark. Then, control the low beams with a separate switch, so you can leave the truck running in neutral when you are hooking up trailer, loading up the truck or doing recovery operations at night.

Using the peashooter-gringeltaube switch has a benefit of not accidental leaving the reverse lights on when driving.

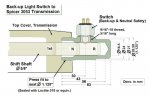

After much thought, I decided to pull power from the #75 brake light switch circuit. This has multiple benefits: The truck retains it's mil-spec capability of being operate without any lights and the #75 wiring is near the transmission, so the wiring won't be difficult to run. Note: My '87 A2C with dual circuit brakes had #175 tags on the wires, I think that's an error. Yours should be #75.

So, all that decided, I ordered the switch from peashooter and requested it with packard connectors. I bought plenty of high quality wire and 100' of Grote's asphalt covered cloth wiring loom (like what the front composite harnesses are wrapped in under the fenders).

Installing the switch:

Remember, both wires going to the brake light switch are #75, so you'll need to use a multimeter or test light to identify the input/output (you want the one that's always hot when the light switch is in service drive or brake light operation.

Obviously now is the time to upgrade to the air operated switch.

Once you've got your power source, run it up to the switch. Make sure to protect it from chafing hazards and make sure it isn't in the way of future service operations.

Now that you've got the switch installed and powered it, you need to run the switched wire back to the reverse lights. Same thing as before, make sure it's protected from chafing an pinching hazards, etc.

More in next post.

![20150124_152104[1].jpg 20150124_152104[1].jpg](https://www.steelsoldiers.com/data/attachments/374/374502-079ceefe077f78434b85fcaed5279516.jpg)

![20150124_152130[1].jpg 20150124_152130[1].jpg](https://www.steelsoldiers.com/data/attachments/374/374506-892421b72e776d820117b8f2bd7de206.jpg)