Another Ahab

Well-known member

- 18,043

- 4,693

- 113

- Location

- Alexandria, VA

Cool vid:Video of truck running with valve covers removed:

- Ingenious invention that internal combustion engine.

Steel Soldiers now has a few new forums, read more about it at: New Munitions Forums!

Cool vid:Video of truck running with valve covers removed:

Cool vid:

- Ingenious invention that internal combustion engine.![Thumbs Up [thumbzup] [thumbzup]](https://www.steelsoldiers.com/images/smilies/icon_smile_thumzup.gif)

It's there but difficult to see in the video. These engines don't splash oil around the valve areas like small block Chevrolets & modern engines.Maybe i'm just use to modern engines, But where is the oil? It looks like the valves are running dry

The best way to adjust valves is with the engine running. That way your not worrying about getting to operating temperature since it is already there.Today I knocked out my first axle boot replacement. It went surprisingly well. I had read horror stories of having to use clamps to hold the boot/wire in place and needing extra people, etc. It went on w/out any issues.

After installing the new drivers boot, I checked the pass boot and it's in worse shape than the boot I removed from the drivers side, so I'm going to flip the old drivers boot 180* and install it on the pass side tomorrow (so the small tear is on top vs bottom and I'll tape the hole enough to get me by for the weekend). After this weekend trip, I'll order a new one for the pass side (I don't have time to get a new one here before we head out).

The valve adjustment was a failure. I really needed soldier #2 to turn the drive shaft while I watched the valves. However, it did give me a chance to examine the valves of the engine to check for anything major. Thankfully everything looked and sounded normal.

Video of truck running with valve covers removed:https://www.youtube.com/watch?v=TD0air54LoU

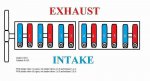

Valve covers removed:

View attachment 704579

new boot:

View attachment 704578

It'll drive you bananas when you get two sets of advice that seem to directly contradict one another.Y'alls reply posts are making me wonder what to do now (since I still need to do the adjustment... I want to get it right). Everything I read on the forum says to do the adjustment with the engine cold (including a post from DH whose opinion I trust). I'm searching through my TMs to see what they say, so far I can't find the section.

Everyone has their own way of doing the same thing. I was told the clearance values were different in intake and exhaust because of thermal expansion once the motor is running. SO personally, I set them cold as stated in the TM. If you do it while its running and warm, you may get a false gap. I'm sure others have more/better insight, but thats how I do it.Y'alls reply posts are making me wonder what to do now (since I still need to do the adjustment... I want to get it right). Everything I read on the forum says to do the adjustment with the engine cold (including a post from DH whose opinion I trust). I'm searching through my TMs to see what they say, so far I can't find the section. Here is one example (see attachment) of a post stating to do the adjustment cold vs hot. What are y'alls thoughts?

View attachment 704646

Agreed X10000. I'm going to stick with the TM and set it w/the engine cold.Everyone has their own way of doing the same thing. I was told the clearance values were different in intake and exhaust because of thermal expansion once the motor is running. SO personally, I set them cold as stated in the TM. If you do it while its running and warm, you may get a false gap. I'm sure others have more/better insight, but thats how I do it.

Y'alls reply posts are making me wonder what to do now (since I still need to do the adjustment... I want to get it right). Everything I read on the forum says to do the adjustment with the engine cold (including a post from DH whose opinion I trust). I'm searching through my TMs to see what they say, so far I can't find the section. Here is one example (see attachment) of a post stating to do the adjustment cold vs hot. What are y'alls thoughts?

View attachment 704646

Naps are good.Now you did it.

Now I can't even remember if the multi fuel engine has solid or hydraulic lifters/tappets.

Looked it up for seven minutes and those threads went to everywhere but the answer.

Probably time for a nap.

Hot and running, loosen until tick, tighten until tick goes away, correct?I'll just say this and let you decide. I've been a heavy diesel mechanic for 45 years. Recently retired (2 years) . In all that time the best way to adjust the valves was hot and running. The reason the TM says to do it cold is so that the silly GI's didn't' hurt themselves. Really that is the only reason. I have "factory" service manuals going back to the turn of the 20th century (1900) and they all said to adjust valves hot and running. In todays world though due to liability and insurance and State L&I most manufactures say to adjust them with the engine cold. It takes skill and practice to adjust them hot and running so just do it as the TM says to do.

Actually what you do is loosen them and using the proper feeler gauge install it between the valve and rocker and adjust until you can just barely remove the feeler gauge. It really isn't all that complicated just takes a bit of coordination since the valves are jumping up and down. You learn to allow the gauge to "float" in your hand while doing this. When done properly you will have a better adjustment then doing it cold. Engines run smooth as hot butter !Hot and running, loosen until tick, tighten until tick goes away, correct?

Thanks