- 6,683

- 14,266

- 113

- Location

- Hawthorne, NV.

You are absolutely right. Good job!I’m fortunate to have a set of @peashooter’s flex lines on my truck. That was money well spent!

Steel Soldiers now has a few new forums, read more about it at: New Munitions Forums!

You are absolutely right. Good job!I’m fortunate to have a set of @peashooter’s flex lines on my truck. That was money well spent!

That would be nice. My fenders are disintegrating from rust. There's no sense in my patching them, because new rust holes would soon appear elsewhere. It's the TDG (Truck Destroyer-Granular) they put on the roads here in the Winter. I'm going to put some kind of undercoating on the new ones. I really need to be spending the money on my house. Oh well.The TMs are the best place for information. I would love to have a couple of NOS front fenders to salt away, along with some hoods & hard tops.

I have a question for the M35 owners. I did a few searches on it and came up with nothing relevant. I'm wondering if any of you know what the proper adjustment is for the throttle pedal stop bolt that protrudes from the floor just under the top of the pedal? I'm thinking that if mine is too high it could be restricting how much throttle/fuel I can give my engine. I might have to drag out my TMs and see if I can find something on it. I would appreciate any insights you may have. Going to try and get down to Eastern Surplus this week and pick up two NOS front fenders and a J-pipe if all goes well.

Thank you for the picture and explanation cattlerepairman! I actually did the above task when I installed a new throttle rod and hand throttle cable. I also replaced the pedal and it's floor hinge. It was binding from corrosion. I need a new throttle return spring now. They get weak over time. Maybe I'll revisit the linkage adjustment. It's always possible I didn't get it exactly right. Queen Lola should be coming out soon for the Spring thaw yes?Info from TM 9-2320-361-24-1 work package 0070 00

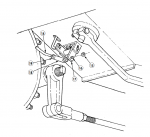

1. Remove locknut (15) from threaded stud (16) and remove threaded stud (16) of ball joint ( 18 from lever (17). 2. Loosen nut (19) on accelerator rod (14). NOTE Rod is shortened by turning ball joint clockwise on rod and lengthened by turning ball joint counterclockwise on rod. 3. Shorten or lengthen accelerator rod (14) until threaded stud (16) of ball joint ( 18 will freely slide into hole of lever (17). 4. Install locknut (15) on threaded stud (16) and tighten locknut (15). 5. Tighten nut (19) on accelerator rod (14). 6. Connect battery ground cable (WP 0126 00). 7. Start engine (TM 9-2320-361-10) and check throttle for proper operation. 8. Lower and secure hood (TM 9-2320-361-10). 9. Release parking brake and remove wheel chocks (TM 9-2320-361-10)

View attachment 827714

I did not find any reference to the stud/bolt that limits accelerator pedal travel. I would think that, with the linkage properly adjusted, soldier 1 would slowly depress the accelerator until it hits the stud while soldier 2 checks at the IP that it corresponds to max WOT. If not...adjust stud!

We have a good 2ft of snow on the ground and Spring thaw is still weeks away! Then the soil has to dry so I can actually park her on the grass. Weeks and weeks to go!. Queen Lola should be coming out soon for the Spring thaw yes?

Good idea. I had one break several years ago. Not a pleasant experience.Just take the truck and drive and learn about it. There will be many for sale.

Rust never stopped a WAR.

Double spring it, 40 to 70 year old stuff might need help, anyhow, it is a safety issue.

Do Your self a flavor and Put double spring somehow,then after that, fix everything else.

This is just an example on mine without even the original steering box, but you'll get the idea.

Springs wear out, just like us.

Dipstick, you can pick up the spring in Franks post from one of our vendors, Part Number 7539129 NSN 5360-00-753-9129 Spring Helical. If all else fails you can find them on e-bay.I like Frank's spring idea. It's hard to find a suitable spring at any of the hardware and automotive stores. I think I even tried a Holley carburetor spring once. It didn't have enough tension. I'm going to keep on the hunt. As far as the rust goes I'm just trying to keep my truck decent looking. Plus, in PA if you have rust holes you won't pass inspection.

Shhhhhhhhh! Murphy is messing up a wheel seal as you speak!View attachment 827817 Got the wheel cylinder replaced, everything cleaned up, and the wheels back on. Took it for a 30 mile run and all is well.

work work workG'day everyone,.....

~I wanna do a few small jobs and take her a for a nice long run.

Aussie.

work work work