- 4,333

- 1,943

- 113

- Location

- Edmond, Oklahoma

5+ years and zero issues!

Now I need a paint job………

Now I need a paint job………

Attachments

-

128.4 KB Views: 35

Steel Soldiers now has a few new forums, read more about it at: New Munitions Forums!

I went with the hella housings and led bulbs. I wanted to keep it looking stock, except for the 6" lift and hmmwv wheels. LolNow for a set of Truck-Lite LED Headlights……:

Thank you! Looking good with her friends..

She is looking better and better...

Really nice!

If you made the decals and they turn out well, you should consider selling them!Decals came out really nice! Now to see if they hold up.

Very nice looking factory freshThank you Cucvrus! Bridge plate installed!

Blackout marker lights are LED. One of the first applications.Replaced a faulty Blackout front bumper light.

Was intermittent and had a short inside I assume.

Installed new one and all work great once again.

I know they’ll never be really used, just like to have everything on truck working correctly.

Your truck looks great.Swapped the Goodyear MTRS load E's to some BFG Baja's load D. What a ride difference from E to D.

its a custom mount I built. It holds a 12k smittybuilt winch. I wanted the highest clearance mount possible for the rock crawling we do and it can’t stick out past the bumper to hurt approach angle. Bit of a photo dump but gives anyone who wants to copy it a good idea how it’s made.I like the truck. I'm not taking mine as far but I'm curious about your hidden winch.

Thank you! Much smoother and quieter. I've always been a BFG fan. I was sent the mtrs by accident,. So now they went on my m1151.Your truck looks great.

What's the ride difference, smoother? quieter?

Your welding caught my eyes, very professional, excellent work all around.its a custom mount I built. It holds a 12k smittybuilt winch. I wanted the highest clearance mount possible for the rock crawling we do and it can’t stick out past the bumper to hurt approach angle. Bit of a photo dump but gives anyone who wants to copy it a good idea how it’s made.

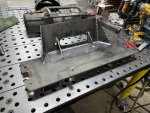

It’s a 1/4” plate base with 2x3 square tube 3/16” wall cut diagonally and 1/2 to give the 1/4” plate support

View attachment 883087

1/4” gussets on the back. My gen 1 design bent in due to lack of gusset size and smashing on rocks (it was all 3/16” steel) Plus the winch line stored against it didn’t help that fact with all the preload

View attachment 883088

View attachment 883089

The winch plate is sized to fit snugly in between the perches and swings down. Install the winch, then swing the assembly up and bolt up front after drilling some holes. The free spool handle is clocked to the back and it’s easy to reach.

View attachment 883090

and that’s it. The 12k winch clears the core support by 3/8” or so. It’s close but never had issues with it.

View attachment 883091

Awesome CUCV and great fab work, man!Did a whole lot of work lately, truck is a bit out of the norm for this group but designed and built an eco cage for it. 100% TIG welded as well.View attachment 883084View attachment 883085