M1009 project.

Sunday.

1. Harmonic balancer - My puller tool stripped out and was turning the engine over, so I had to use my backup puller. So now I need to buy a new one so I always have a spare. (Perfect example why I have a spare)

2. Rebuilt my one of my alternators, the other was a remanufactured and was OK. I still took it apart to make sure it was OK and clean inside.

3. While I had the the alt. and pulleys out I cleaned the grease and painted the parts black. I found that a nut was missing on the passenger side alt. bracket, so I replaced that. Also made sure all blots on the water pump were tight.

4. Put my starter back in as I had it out checking the flywheel that has broken teeth in random spots.

5. Hosed down the radiator before I put everything back on, it really cleaned out allot of dirt in there.

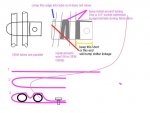

6. Removed the diode from the horn relay that goes back to the headlight fuse/system. Known problem that can develop that puts too much load on the headlights circuit. With that I also removed the capacitor on the wipers and horn.

7. Took a break and got lunch.

8. cleaned up my mess from working on the truck all day.

9. Made sure everything was all tight and in place and let it run for about an hour. I need to burn off this old fuel and also looked for any leaks.

So I did allot of work on the M1009 today, but still allot more to do on it. Have to get the flywheel replaced, but I have to drive it first to make sure the trans is OK. No point doing that work replacing that if the trans is bad. Something I am nor going to do, mostly because my driveway is not level and too dangerous having it all up on jack stands. So I will have my mechanic do that work.