Replaced the halogens with Amazon LEDs, but had to pull the side marker lights to get the LEDs to work right. Got new sockets for the side markers on the way. Pulled the trailer brake system and most of the snow plow wiring out to clean up behind the dash. Put the front bumper back on with some random shop bolts. Next up is deleting the load sensing valve and most likely running new hard/soft lines to the passenger's rear brake followed by a rear brake job.

-

Steel Soldiers now has a few new forums, read more about it at: New Munitions Forums!

What have you done to your CUCV today/lately - Part 2

- Thread starter Warthog

- Start date

More options

Who Replied?Without necroposting, and if this isn't the correct spot, feel free to correct me, but if anyone has done the load sensing valve delete can you message me? It looks like a fairly simple procedure, but I want to see if there are any tips or tricks to make sure I don't run into too many hang-ups.

- 337

- 528

- 93

- Location

- Inverness, Florida

The TSB recommending removal and the approved GM removal procedure:

GMC NUMBER: 88-T-151

GROUP: 5 - Brakes

DATE: August, 1988

CORPORATE NUMBER: 865010R

SUBJECT: REAR BRAKE SENSITIVITY - HEIGHT SENSING VALVE REMOVAL

MODELS: 1984-86 C/K 3500 AND 1987-88 R/V 3500

THIS BULLETIN IS A REVISION OF TRUCK SERVICE BULLETIN 85-B-79, DATED MAY, 1985, UPDATING FOR MODEL YEARS 1984-1988.

1984-1986 C/K 3500 and 1987-1988 R/V 3500 series trucks are equipped with a rear suspension height sensing device that optimizes the brake proportioning valve setting for the load the vehicle is carrying. The height sensing system adjusts the brake balance in vehicles subjected to a range of loading conditions. Occasionally, vehicle modifications by body builders or owners influence the height sensing device. If a vehicle has had rear suspension modifications that affect its trim height or the spring rate, and the driver comments about the brake modulation characteristics of the vehicle, it is recommended that the height sensing system be removed and the brake system be revised as described below:

Parts listed below are currently available from GMSPO.

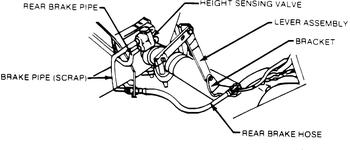

1. Detach rear brake hose from lever and bracket assembly. Reference Figure No. 1.

2. Remove lever assembly and bracket from axle.

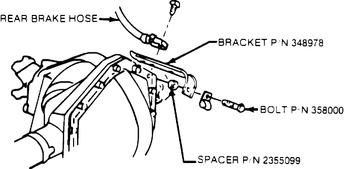

3. Install rear brake hose bracket (P/N 34897 and spacer (P/N 2355099) with a 3/8-16 x 1.38 bolt (P/N 358000 - shorter bolt removed in Step No. 2) in the upper cover hole. Reference Figure No. 2. Use Loctite 75 or equivalent on the bolt threads.

and spacer (P/N 2355099) with a 3/8-16 x 1.38 bolt (P/N 358000 - shorter bolt removed in Step No. 2) in the upper cover hole. Reference Figure No. 2. Use Loctite 75 or equivalent on the bolt threads.

4. Attach brake hose to bracket with bolt from original installation.

5. Install a 3/8-16 x 1-3/4 bolt (P/N 9439637 - longer bolt removed in Step No. 2) through spacer P/N 14055556 (removed in Step No. 2) in remaining axle cover attaching hole. Use Loctite 75 on bolt threads or equivalent.

6. Disconnect brake pipes from height sensing valve and brake hose, and discard short brake pipe. Reference Figure No. 1.

7. Remove and discard height sensing valve, bracket, and bolts.

8. Carefully reposition the rear brake pipe, and connect it to the rear brake hose.

9. Bleed and test brake system per Section 5 of the appropriate Light Duty Service Manual.

I found this after a quick search online. Somewhere on a computer I have a copy of the TSB. Courtesy of someone on this forum.

GMC NUMBER: 88-T-151

GROUP: 5 - Brakes

DATE: August, 1988

CORPORATE NUMBER: 865010R

SUBJECT: REAR BRAKE SENSITIVITY - HEIGHT SENSING VALVE REMOVAL

MODELS: 1984-86 C/K 3500 AND 1987-88 R/V 3500

THIS BULLETIN IS A REVISION OF TRUCK SERVICE BULLETIN 85-B-79, DATED MAY, 1985, UPDATING FOR MODEL YEARS 1984-1988.

1984-1986 C/K 3500 and 1987-1988 R/V 3500 series trucks are equipped with a rear suspension height sensing device that optimizes the brake proportioning valve setting for the load the vehicle is carrying. The height sensing system adjusts the brake balance in vehicles subjected to a range of loading conditions. Occasionally, vehicle modifications by body builders or owners influence the height sensing device. If a vehicle has had rear suspension modifications that affect its trim height or the spring rate, and the driver comments about the brake modulation characteristics of the vehicle, it is recommended that the height sensing system be removed and the brake system be revised as described below:

Parts listed below are currently available from GMSPO.

1. Detach rear brake hose from lever and bracket assembly. Reference Figure No. 1.

2. Remove lever assembly and bracket from axle.

3. Install rear brake hose bracket (P/N 34897

4. Attach brake hose to bracket with bolt from original installation.

5. Install a 3/8-16 x 1-3/4 bolt (P/N 9439637 - longer bolt removed in Step No. 2) through spacer P/N 14055556 (removed in Step No. 2) in remaining axle cover attaching hole. Use Loctite 75 on bolt threads or equivalent.

6. Disconnect brake pipes from height sensing valve and brake hose, and discard short brake pipe. Reference Figure No. 1.

7. Remove and discard height sensing valve, bracket, and bolts.

8. Carefully reposition the rear brake pipe, and connect it to the rear brake hose.

9. Bleed and test brake system per Section 5 of the appropriate Light Duty Service Manual.

I found this after a quick search online. Somewhere on a computer I have a copy of the TSB. Courtesy of someone on this forum.

Yup! Found that here too. Like I said, it LOOKS simple, I just want to make sure it IS that simple from someone who's done it!The TSB recommending removal and the approved GM removal procedure:

GMC NUMBER: 88-T-151

GROUP: 5 - Brakes

DATE: August, 1988

CORPORATE NUMBER: 865010R

SUBJECT: REAR BRAKE SENSITIVITY - HEIGHT SENSING VALVE REMOVAL

MODELS: 1984-86 C/K 3500 AND 1987-88 R/V 3500

THIS BULLETIN IS A REVISION OF TRUCK SERVICE BULLETIN 85-B-79, DATED MAY, 1985, UPDATING FOR MODEL YEARS 1984-1988.

1984-1986 C/K 3500 and 1987-1988 R/V 3500 series trucks are equipped with a rear suspension height sensing device that optimizes the brake proportioning valve setting for the load the vehicle is carrying. The height sensing system adjusts the brake balance in vehicles subjected to a range of loading conditions. Occasionally, vehicle modifications by body builders or owners influence the height sensing device. If a vehicle has had rear suspension modifications that affect its trim height or the spring rate, and the driver comments about the brake modulation characteristics of the vehicle, it is recommended that the height sensing system be removed and the brake system be revised as described below:

Parts listed below are currently available from GMSPO.

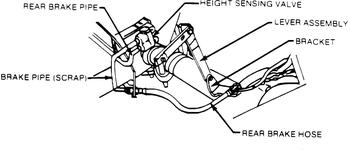

1. Detach rear brake hose from lever and bracket assembly. Reference Figure No. 1.

2. Remove lever assembly and bracket from axle.

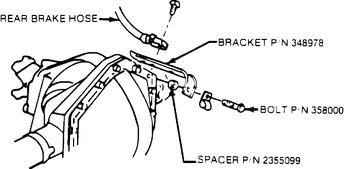

3. Install rear brake hose bracket (P/N 34897and spacer (P/N 2355099) with a 3/8-16 x 1.38 bolt (P/N 358000 - shorter bolt removed in Step No. 2) in the upper cover hole. Reference Figure No. 2. Use Loctite 75 or equivalent on the bolt threads.

4. Attach brake hose to bracket with bolt from original installation.

5. Install a 3/8-16 x 1-3/4 bolt (P/N 9439637 - longer bolt removed in Step No. 2) through spacer P/N 14055556 (removed in Step No. 2) in remaining axle cover attaching hole. Use Loctite 75 on bolt threads or equivalent.

6. Disconnect brake pipes from height sensing valve and brake hose, and discard short brake pipe. Reference Figure No. 1.

7. Remove and discard height sensing valve, bracket, and bolts.

8. Carefully reposition the rear brake pipe, and connect it to the rear brake hose.

9. Bleed and test brake system per Section 5 of the appropriate Light Duty Service Manual.

I found this after a quick search online. Somewhere on a computer I have a copy of the TSB. Courtesy of someone on this forum.

- 3,382

- 1,426

- 113

- Location

- The actual midwest, NM.

Do it. Then decide how simple it was. Or not.Yup! Found that here too. Like I said, it LOOKS simple, I just want to make sure it IS that simple from someone who's done it!

Abbylind

Member

- 284

- 14

- 18

- Location

- Palm Harbor FL & NM

Happy 4th to everyone!

Hooked up the batteries to my M1008 and checked tire pressures after sitting for 6+ months...took it to the dump with a load of tree limbs...drove like a scalded dog!

Hooked up the batteries to my M1008 and checked tire pressures after sitting for 6+ months...took it to the dump with a load of tree limbs...drove like a scalded dog!

Another Ahab

Well-known member

- 18,038

- 4,690

- 113

- Location

- Alexandria, VA

Glad to heart your rig is running right fine, Abbyblind.Happy 4th to everyone!

Hooked up the batteries to my M1008 and checked tire pressures after sitting for 6+ months...took it to the dump with a load of tree limbs...drove like a scalded dog!

A Blazing Fourth to you, Brother. Long Live the Republic!!

LT67

Well-known member

- 660

- 507

- 93

- Location

- Bowdon, GA

I don't drive my 85' M1008 as much as I used to. Only a handful of times each month. The 86 M1008 aka theHappy 4th to everyone!

Hooked up the batteries to my M1008 and checked tire pressures after sitting for 6+ months...took it to the dump with a load of tree limbs...drove like a scalded dog!

On that note I looked at a Vortech 350 to swap into the 86' M1008. The ole 6.2 is losing more compression and it needs to be replaced. I'll keep all of the diesel parts for future use..

Another Ahab

Well-known member

- 18,038

- 4,690

- 113

- Location

- Alexandria, VA

Great pics, Marauder4:

-New material is always encouraging, and good for the spirit to see it installed!

I figure that she's only got 35k on her in 40 years. Might as well replace the parts that are worn. But with the thicker tires on her, the driver's side tire already ate my BRAND NEW boot! So spacers are on the way now too...damnit!Great pics, Marauder4:

-New material is always encouraging, and good for the spirit to see it installed!

True Knight

Active member

- 674

- 179

- 43

- Location

- San Pedro, CA

If you still have problems with the wobble, might need to put a large washer on top of the kingpin springs to increase the preload due to the heavier tires. Looks like you have everything else fixed.

I have the inner tie rod on the way, so once I replace that (it's joint is loos as well) and check the damper I'll worry about shimming it up. But that is an awesome idea!If you still have problems with the wobble, might need to put a large washer on top of the kingpin springs to increase the preload due to the heavier tires. Looks like you have everything else fixed.

ehuppert

Active member

- 282

- 141

- 43

- Location

- Upstate NY

Adjust steering stop on knuckle to keep boot safe! Slightly decreases turning radius but minimal! When I went to the 285/75's i had the same issue.

Replaced tie-rod, recentered the center link, and installed 1.5" spacers. Steering is tight and right and the death-wobble is cured! Now for an alignment.

Attachments

-

151.3 KB Views: 28

-

113.6 KB Views: 29

-

77.8 KB Views: 29

- 3,382

- 1,426

- 113

- Location

- The actual midwest, NM.

You may want to clean off the hub surface that the spacers rest against. And that doesn't look like much thread engagement on the bolts holding it on.

Either way, don't forget to retorque the spacers after a little driving.

Either way, don't forget to retorque the spacers after a little driving.

Another Ahab

Well-known member

- 18,038

- 4,690

- 113

- Location

- Alexandria, VA

Who doesn't like a story with a happy ending?!Replaced tie-rod, recentered the center link, and installed 1.5" spacers. Steering is tight and right and the death-wobble is cured! Now for an alignment.

Is it your Daily Driver, Marauder4?

It will be!Who doesn't like a story with a happy ending?!

Is it your Daily Driver, Marauder4?

Spence

Member

- 26

- 74

- 13

- Location

- Massachusetts

I have been resealing the engine in my M1010. Looking for a part missing from my injection pump and it seems to be unobtainium. Will get everything cleaned up and reassembled in the mean time. Maybe the part is in the sump. Will find out tomorrow.

Attachments

-

113.1 KB Views: 29

- 112,396members

- 166,096threads

- 2,338,986posts

- 1,127online users