From my original post, you can see that I am having trouble with the bolts that hold the driver-side alternation bracket to the cylinder head. The two bolts do double duty for the power steering bracket as well... yeah, that one.. Post #17 shows the two bolts. The one on the right is chewed up- it's a mystery to me how it would get that way inside the block?!?

The one on top left tumbled out as I removed the P/S bracket. There was about two threads left in the block where it had sheared off and worn against the piece that came out with the P/S bracket. I could barely nip the threads with pliers, but it would not turn out. I Dremeled a notch in the face, but a sturdy screwdriver could not move it either. Yesterday I hit it with a welder, but could not get the bolt end to meld with a nut. Had better luck welding a 3/16" washer to the broken stub, and was able to turn it out with a vise-grip only to find an unexpectedly short stub. I checked the depth of the hole and discovered another section left in the block?!? After some judicious drilling I was able to baby it out with a HFT extractor.

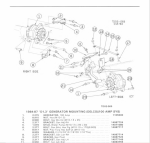

Here's a picture of the 3 piece disaster- the long threaded part held the P/S bracket. The middle piece was the stub sticking out of the block (now with welded-on washer- it's turned 180 degrees the wrong way in the picture), the final piece is still on the extractor. Endeavor to persevere.

Question: What should be used, if anything to keep the brand new bolts from ending up the way this last set looks? Anti-seize? Thread-loc?

I'm chasing the M10 bolt holes before I replace the Alt/brackets and P/S, but I'd like to know what treatment I might use to keep these bolts tight.