- 44

- 11

- 8

- Location

- College Station, TX

Who makes the best aftermarket Air conditioner for M 1008?

Steel Soldiers now has a few new forums, read more about it at: New Munitions Forums!

Which 700R 4 did you use?You might find my experiences enlightening -

Kinda got carried away..... M1028 rebuild

OK I am moving forward with adding AC to my P400 / 700R4 build. After researching all available options, including retrofitting a civilian setup into my M1028, I narrowed my choice down to 2 aftermarket kits - Nostalgic Air and Vintage Air. And after researching both kits, I chose Vintage Air...www.steelsoldiers.com

Does the engine idle up when you turn AC on if so how? Do you have any suggestions for a turbo? I need an antenna mount do you know of any close to our area? Did I tell you I seen the M1007 driving through caldwell?I have a Nostalgia unit in mine but think a Vintage has got to be better. Here is a video I did about it:

Is there a need to upgrade the fan ( more blades) for the radiator cooling systemI have a Nostalgia unit in mine but think a Vintage has got to be better. Here is a video I did about it:

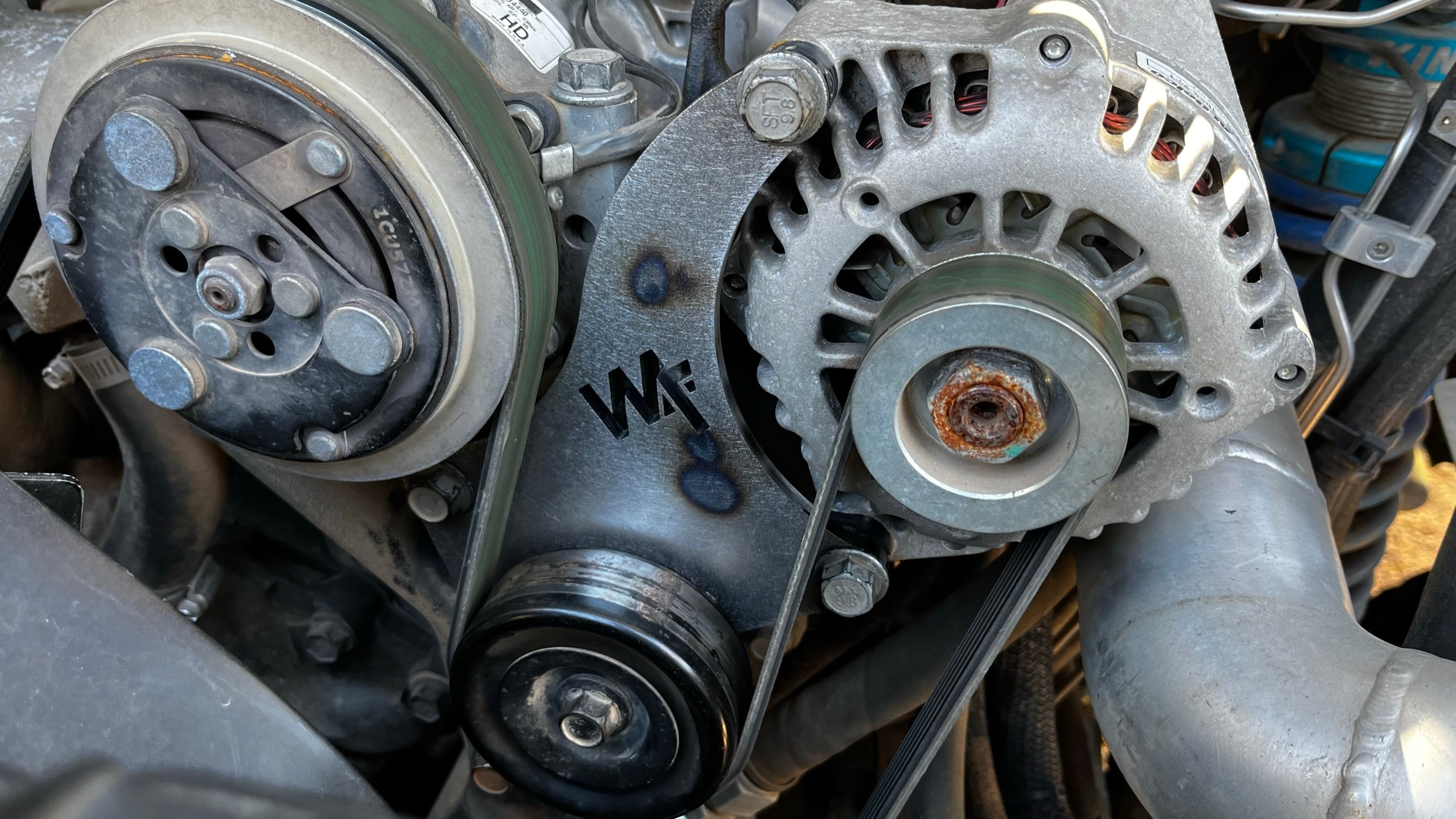

765R4 from Bowtie Overdrives in California Bowtie Overdrives - View ItemWhich 700R 4 did you use?

The only things on the CUCV's that are 24V are the starter and the slave port in the grille. Everything else is 12V. You can pull 24V for your compressor off the 24V Buss located just behind the rear battery above where the VA plate attaches. Not sure how much draw the compressor will consume, but I would think two 100-amp alternators would be more than enough to supply the power. It will be important to assure both alternators are operating properly and all belts are tight. If your electric compressor plan works, it could solve a lot of problems for other owners of CUCV's who want to install A/C.Currently bringing in the stuff to work through this myself. I have installed 3 vintage air systems on some of my K10 projects. I picked up a CUCV and plan on adding AC using a vintage Air internal system and running a Electric compressor. The truck I bought has 2 large batteries and 2 alternators, so it squishes the conversation about too much draw on the batteries.

This vintage Air system

24v version of this with harness

Probably going to have to use some sort of relay to integrate the 2 systems as I don't care to convert over to 12v. I haven't messed around under the dash or put a meter to the block over on the driver's side but my guess is there is some 12v stuff already in the interior.

This is what the VA unit looks like from the cab to the under hood. This should be really close to being under the battery box.

EDIT: I looked at the link, that compressor uses 850w of power to provide 2600w of cooling. This is typical, as the coefficient of performance (COP) for a heat pump is almost always much greater than 1.I just now looked at the Ebay ad for that compressor

24v version of this with harness

and saw that at 24V the compressor requires 2600W of power to provide 850W of cooling. I'm no electrical engineer so maybe somebody will chime in with how this can be provided by two 100-amp alternators. Hope this helps.