Csm Davis

Well-known member

- 4,170

- 403

- 83

- Location

- Hattiesburg, Mississippi

Nice one bud, i see you are watermarking your drawings now? Did someone steal cotton tops drawings?

Sent from my SM-G930V using Tapatalk

Steel Soldiers now has a few new forums, read more about it at: New Munitions Forums!

Nice one bud, i see you are watermarking your drawings now? Did someone steal cotton tops drawings?

That would work but would take alot of modifications. What I'm talking about would require no mods to the stock winch/pulleys. Heres a very quick, very ugly drawing in ms paint. Don't spew your coffee on the keyboard when looking at these fine, artistic abilities haha.

I have sunk a wrecker 936A1 to the bumper going downhill, worst possible scenario and yeah it pulled every pinetree we hooked to, by the way why use tree savers when you are just sucking the whole thing out of the ground? Finally got all but 5 wraps off rear drum and hooked to massive oak approximately 12-15' in circumference and pulled it out backwards,that big oak was shaking like king Kong was about to rip it out. I have come up with a plan to never have to worry about an anchor point again, I will share it later.The winches will likely rip out what ever they are hooked to... a BFT is going to become an uprooted Tree shortly,,,,,,,,, I have nightmares about this day......

I have sunk a wrecker 936A1 to the bumper going downhill, worst possible scenario and yeah it pulled every pinetree we hooked to, by the way why use tree savers when you are just sucking the whole thing out of the ground? Finally got all but 5 wraps off rear drum and hooked to massive oak approximately 12-15' in circumference and pulled it out backwards,that big oak was shaking like king Kong was about to rip it out. I have come up with a plan to never have to worry about an anchor point again, I will share it later.

Think I like this setup witha few different pulleysThat would work but would take alot of modifications. What I'm talking about would require no mods to the stock winch/pulleys. Heres a very quick, very ugly drawing in ms paint. Don't spew your coffee on the keyboard when looking at these fine, artistic abilities haha.

View attachment 672875

Green is the boom. The grey circles are the stock winch and pulley. Red is the second winch concept that I'm talking about. Red circle on the left would be the second winch. Red circle on the right would be it's pulley mounted to the main boom. If needed could easily mount it to the end of the inner boom using the pin location that the stock winch uses for a double line rigging.

I have sunk a wrecker 936A1 to the bumper going downhill, worst possible scenario and yeah it pulled every pinetree we hooked to, by the way why use tree savers when you are just sucking the whole thing out of the ground? Finally got all but 5 wraps off rear drum and hooked to massive oak approximately 12-15' in circumference and pulled it out backwards,that big oak was shaking like king Kong was about to rip it out. I have come up with a plan to never have to worry about an anchor point again, I will share it later.

Sent from my SM-G930V using Tapatalk

The fluted drum only sets the first lay of cable, it does not restrict the cable to one wrap.This would be a useful addition - assuming you are intending on competing in the local wrecker market, though the rear lift is only suited to military bumpers as opposed to an underlift.

There is, but do you want to add that much weight forward of the pivot point? We have previously discussed moving the stock hoist winch to the rear of the boom - above the tool boxes, which will add weight to the front of the truck and add to the overall capacity of the crane.

I think the bigger issue, is the fluted drum which restricts the winch to one layer, which with a 3 part setup, will only allow the hook to reach the ground right under a full stick.

The optimum mod would be to change the fluted drum for a smaller diameter smooth one (massively increasing cable capacity/recovery reach), move it to the end of the boom, then add a second one above it or simply replace the whole setup with two smaller civi hyd winches mounted axially or stacked, at the end of the boom like civi rotators.

Time for another "concept" sketch maybe???????

I have sunk a wrecker 936A1 to the bumper going downhill, worst possible scenario.....< snip> I have come up with a plan to never have to worry about an anchor point again, I will share it later.

I didn't think there was any room between the top of the fluted layer and the under side of the boom for a second layer......The fluted drum only sets the first lay of cable, it does not restrict the cable to one wrap.

Let me guess - a track skid steer that mounts to the back of the wrecker like a Moffett fork lift on a sheet rock truck, that has a monster ground spade instead of the bucket???????

View attachment 672933

Let me guess - a track skid steer that mounts to the back of the wrecker like a Moffett fork lift on a sheet rock truck, that has a monster ground spade instead of the bucket???????

View attachment 672933

I should be ok ... I have friends currently collecting the 8 ground anchor plates and 64 hex pins (not to mention a load of spare sledge hammer handles) that I'll be carrying (Aussie/Brit equivalent to Bii) for self recovery when there is nothing around...

As we all await the unveiling with baited breath.......

You guys are funny, NOT!

I tried that remote skid steer, fell into the same hole before being a usable anchor.....

65,000 lb winch, maybe off HET.Zeb

That Mort winch looks a lot like our rear drag winches..... though with the extra gear on the side, I think it came from a Holmes,,,, HMMM.... If I had a fortune laying around that I wanted to reduce to piddlings.... I would snag a few of the 816 or 936 rear drag winches and set em up this way.... Niche market...... or Starvation plantation waiting on a sell....

Yes I know what a M looks like but wanted to emphasize the spread.Er... I think an "Up side down W"..... is an 'M'. : )

Jeff - that sounds like a reeeeeal load of extra work! I thought banging in 64 ground anchor pins was a chore but digging that much .. Wowza.

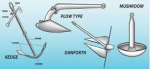

Have you seen the US style ground anchors that were Bii back in the M1A1/M62 days? Enough of them should add up to the ground reaction force needed to self recover. Even an oversize boat anchor (self setting and reverse winch removal) has been discussed before..

I do realise that you are trying to utilise stuff that is already carried on the truck.

._._._._._._._._._._._._._._._._._._._._._._._._._._._._._._._._._._._._._._._._

Try this for an idea........

Boat anchor for the self digging function being the objective.

Using tow bar and support leg base plates.

Add a sub-assembly bracket that will utilise above. (Maybe only 10 lbs for added weight over already carried Bii)

Assemble with pins like the ground spade for HEMTT wrecker (M984E1/A4 etc.)

Towbar on it's side (one leg above the other) for the spine, base plates for the self digging flukes, sub-assembly to be fab'd to attatch flukes to towbar at correct 'digging' angle to lower towbar leg and braced off of top towbar leg. (Attach a 10' chain to heel - subframe or towbar - [where foot goes] for retrieval when buried deep.)

There has to be Naval/Marine Architecture studies/research for the geometry/calculations for self digging anchors ... ?

I think I understand your question...Would that anchor setup try to unbury itself by rotating the back end upwards?

Gotcha, that makes sense.Further to earlier post re ground anchor.

Assembled from wrecker Bii with added "combining bracket" - this is the concept sketch.

View attachment 673079