welldigger

Active member

- 2,602

- 16

- 38

- Location

- Benton LA

Dibs on the dt466e.We have a perfect running DT466E and MaxxForce 7 that we are getting ready to discard at my work. Sorry, we are not throwing away the ISX or ISB's yet...

Steel Soldiers now has a few new forums, read more about it at: New Munitions Forums!

Dibs on the dt466e.We have a perfect running DT466E and MaxxForce 7 that we are getting ready to discard at my work. Sorry, we are not throwing away the ISX or ISB's yet...

It sounds attractive right now.We have a perfect running DT466E and MaxxForce 7 that we are getting ready to discard at my work. Sorry, we are not throwing away the ISX or ISB's yet...

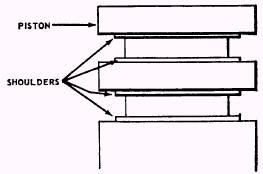

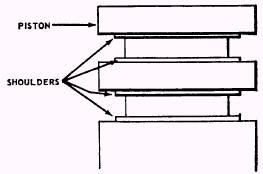

"Make another complete inspection after cleaning the piston. Check all parts for any defects that could require replacement of the piston. Give particular attention to the ring grooves, especially if the pistons have been in service for a long period of time. A certain amount of enlargement of the width of the grooves is normal, and SHOULDERING of the groove may occur. Shouldering, as illustrated in figure 3-20, results from the “hammering out” motion of the rings. The radial depth of thickness of the ring is much less than the groove depth, and while the ring wears away an amount of metal corresponding to its own width, the metal at the bottom of the groove remains unchanged. ShoulderingLast night we found something interesting with the piston rings. at all.

We cleaned up my old pistons and found the wring grooves on them to be worn enough where they may not handle replacement rings that well. So now I'm looking for LDT pistons. I just don't have any faith in these "New LDS Piston Kits" at all from the lack of the extra compression ring with them and the lack of field tested experience.

Make another complete inspection after cleaning the piston. Check all parts for any defects that could require replacement of the piston. Give particular attention to the ring grooves, especially if the pistons have been in service for a long period of time. A certain amount of enlargement of the width of the grooves is normal, and SHOULDERING of the groove may occur. Shouldering, as illustrated in figure 3-20, results from the “hammering out” motion of the rings. The radial depth of thickness of the ring is much less than the groove depth, and while the ring wears away an amount of metal corresponding to its own width, the metal at the bottom of the groove remains unchanged. Shouldering

Figure 3-20.—Ring groove shoulders due to wear.

usually requires replacement of the piston since the shoulders prevent the proper fitting of new rings

You've just proved my original point about having a load on the engine when dyno testing it. It's like riding a bicycle. Your peddling along going up a slight grade when suddenly the chain comes off. Immediately your legs go flying around and you usually hit the handle bars or something. This is not an old wives tall. Anyone who has run a engine dyno knows from experience what can happen to an engine that is not loaded down properly. I ran the dyno at work for 6 months and even in that short of time I saw some interesting things happen.I never said they fail only for one reason. I said they fail via only a single mode (reason) when exposed to excessive RPM, and that is tensile force pulling the rod apart via piston inertia. To better view this from the opposite end of the same story, a proper running 2 stroke engine never really experiences this because the rod is always in compression force, on both directions of its travel, up and down in the cylinder. It never has to reverse the mass of a piston at high speed and pull it down, as where a 4 stroke rod does. Ever notice a 2 stroke rod has almost no meat on the big end at the crank pin and even the beam can be nearly half the size of a 4 stroke rod? Because it doesn't require it.

I believe I posted some pages from my rebuild book on this topic in post 330.This information is very helpful! Thank you! This is exactly what I see on my old LDT pistons.

This is all good information in your post #330. My rings are tapered and I didn't measure them with a feeler gauge as described. Just a visual observation shows they are worn. Thank you for the updates.

I never said they fail only for one reason. I said they fail via only a single mode (reason) when exposed to excessive RPM, and that is tensile force pulling the rod apart via piston inertia. To better view this from the opposite end of the same story, a proper running 2 stroke engine never really experiences this because the rod is always in compression force, on both directions of its travel, up and down in the cylinder. It never has to reverse the mass of a piston at high speed and pull it down, as where a 4 stroke rod does. Ever notice a 2 stroke rod has almost no meat on the big end at the crank pin and even the beam can be nearly half the size of a 4 stroke rod? Because it doesn't require it.

Not ridiculous. 2 stroke on the upstroke pulls intake charge into crankcase. This is the flywheel momentum pushing the piston up on compression. There is a power stroke of every down cycle. In a properly running 2 stroke engine, at what point does the rod has to physically pull the piston down? This is off topic, apology.Jumping in late here:

Unless you are speaking strictly of 2stroke diesels, saying that 2 stroke rods don't experience tensile stress is ridiculous. They literally suck the intake charge past the reeds, which would have greater pumping loss than a 4 stroke's valve.

And they still have to reverse the direction of travel of the piston, which amounts to way more stress than any of the pumping. And they typically do it at much higher RPM.

Furthermore, the steel is pretty much equally strong in tension and compression. Unless your rods are cast iron, then you will find them to be a bit weaker in tension.

Most of the broken rods I've seen started out as bent rods for one reason or another. They are usually broken clean off, and don't exhibit necking like you would see in a pure tensile failure.

I'm sorry, I was talking out the side of my neck this morning before I had my coffee.Not ridiculous. 2 stroke on the upstroke pulls intake charge into crankcase. This is the flywheel momentum pushing the piston up on compression. There is a power stroke of every down cycle. In a properly running 2 stroke engine, at what point does the rod has to physically pull the piston down? This is off topic, apology.

We are reassembling WC's 465 engine tonight. He wants to hone the cylinders, reassemble with new gaskets, and try again with the same new pistons and rings, this time on diesel and a controlled dyno load for break in.

I hope your using "soft jaws" on that vise.

Using the same pistons didn't work too well the first time, might as well try some goofy sh!t...Hey bud why two different types of pistons in the picture above?

Runs better that wayHey bud why two different types of pistons in the picture above?