Skidpad

New member

- 54

- -4

- 0

- Location

- Nashville, Tennessee

Peakbagger, it ought to be easy to find it from that diagram. Now the question is about this 'inlet piping' and flushing it. Also, was the recommendation for the normal marvel mystery oil or the air tool version since this is for air lines?

FLU Farm, the lack of noticeable dampening on this thing makes me think I'm going to take a swing at the shocks first. From what I can tell, that ought to be manageable, much more so that doing the springs too. Euro-Truck has the Sachs shocks at what appears to be an acceptable price.

So, on to the results of the blood, sweat, and tears from today's work and troubleshooting:

1. I discovered why the buzzer and horn don't work, fuse is shot, of course that may mean that a new fuse will just short out too... any good sources you guys recommend for these GBC fuses?

2. I actually pulled the grease fitting apart on the loader while trying to do maintenance, so, do any of you kind folks know what size this 90 is? (many thanks for your patience as I am learning this new set of heavy machinery skills on the fly)

3. Most troubling part of the whole day - while I was digging a test pit for perk testing the hoe just lost all hydraulics, like instantly. I come to discover that the PTO had disengaged itself. It has a bit of a grinding sound when engaging although the clutch is fully depressed, but for it to completely disengage seems a bit worrisome. I was able to quickly re-engage it in order to restore hydraulic pressure and then I stowed the hoe and drove back uphill.

4. Chasing the air leak, chapter 2. I was able to back off the previously mentioned nut and install some Teflon tape to stop the leak at the bottom of the tee. Now, the nut below it is leaking air from the back. Is there a complete diagram of the air system from A-Z that details where everything is and what it does? I feel like this is going to be a fun week chasing the lea until air only discharges when over pressure. It is worth noting that although I have this leak, I continue to maintain primary air pressure @ the factory prescribed 106 psi and the brake air pressure will respond well over 30-40 psi when the pedal is depressed. What exactly is this valve below my leak? I'm starting to think I need to clean and purge the whole air system with all this talk about buildup, etc... Does air have anything to do with the PTO staying engaged? I wouldn't think so but...

4. I adjusted the parking brake and it will now hold against the hill but I can't help feeling that I'm pulling it out a couple of inches too much. I may see about pulling it out to see how long it measures vs how long it is supposed to be. Picture documentation of that procedure will be provided for reference and locations.

So, observations before serious diagnosis begins.

A. When the SEE was parked nose uphill, the boom would not raise but once I drove back onto level ground it would raise

B. Same orientation, nose uphill, the boom did not have enough guts to come back with enough force to engage the boom lock so I had to drive back uphill with the boom swaying precariously in the upright position. (This combined with the previously mentioned swaying of the ride made for a white knuckle bit of excitement). Again, once on level ground at the top of the hill, the boom had no issue coming back and going over center and I was able to store the boom in the travel lock position.

Any ideas guys? I really need to get these issues worked out before I jump into the quick attach because I have got lots of work to do to get this land ready by next spring. Building a house has it's own series of headaches and I need this little beast working to help me conquer them.

Thanks, I'm whipped today...

FLU Farm, the lack of noticeable dampening on this thing makes me think I'm going to take a swing at the shocks first. From what I can tell, that ought to be manageable, much more so that doing the springs too. Euro-Truck has the Sachs shocks at what appears to be an acceptable price.

So, on to the results of the blood, sweat, and tears from today's work and troubleshooting:

1. I discovered why the buzzer and horn don't work, fuse is shot, of course that may mean that a new fuse will just short out too... any good sources you guys recommend for these GBC fuses?

2. I actually pulled the grease fitting apart on the loader while trying to do maintenance, so, do any of you kind folks know what size this 90 is? (many thanks for your patience as I am learning this new set of heavy machinery skills on the fly)

3. Most troubling part of the whole day - while I was digging a test pit for perk testing the hoe just lost all hydraulics, like instantly. I come to discover that the PTO had disengaged itself. It has a bit of a grinding sound when engaging although the clutch is fully depressed, but for it to completely disengage seems a bit worrisome. I was able to quickly re-engage it in order to restore hydraulic pressure and then I stowed the hoe and drove back uphill.

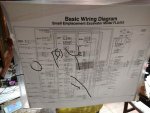

4. Chasing the air leak, chapter 2. I was able to back off the previously mentioned nut and install some Teflon tape to stop the leak at the bottom of the tee. Now, the nut below it is leaking air from the back. Is there a complete diagram of the air system from A-Z that details where everything is and what it does? I feel like this is going to be a fun week chasing the lea until air only discharges when over pressure. It is worth noting that although I have this leak, I continue to maintain primary air pressure @ the factory prescribed 106 psi and the brake air pressure will respond well over 30-40 psi when the pedal is depressed. What exactly is this valve below my leak? I'm starting to think I need to clean and purge the whole air system with all this talk about buildup, etc... Does air have anything to do with the PTO staying engaged? I wouldn't think so but...

4. I adjusted the parking brake and it will now hold against the hill but I can't help feeling that I'm pulling it out a couple of inches too much. I may see about pulling it out to see how long it measures vs how long it is supposed to be. Picture documentation of that procedure will be provided for reference and locations.

So, observations before serious diagnosis begins.

A. When the SEE was parked nose uphill, the boom would not raise but once I drove back onto level ground it would raise

B. Same orientation, nose uphill, the boom did not have enough guts to come back with enough force to engage the boom lock so I had to drive back uphill with the boom swaying precariously in the upright position. (This combined with the previously mentioned swaying of the ride made for a white knuckle bit of excitement). Again, once on level ground at the top of the hill, the boom had no issue coming back and going over center and I was able to store the boom in the travel lock position.

Any ideas guys? I really need to get these issues worked out before I jump into the quick attach because I have got lots of work to do to get this land ready by next spring. Building a house has it's own series of headaches and I need this little beast working to help me conquer them.

Thanks, I'm whipped today...