Well to continue my little tutorial on mounting tires, here I'm installing the assembled tire unit to the wheel.

View attachment 782181 Align the valve stem with the wheel cut-out and lower the tire down at an angle.

View attachment 782182

Then push down the valve stem towards the cut-out and slowly push the tire into the wheel.

View attachment 782183

Once the valve stem is inside the wheel you can then lift the tire up (behind the valve stem area) and it will slid right down on the wheel. This is another reason to use the baby powder. It prevents the friction you normally have with rubber.

View attachment 782184 View attachment 782185

Make sure the valve stem is centered in the wheel cut-out. If it isn't then you can rotate the tire until it is. This is an important step, as it prevents the stem from becoming damaged due to rubbing against the wheel. I've seen many tires leak from this simple problem.

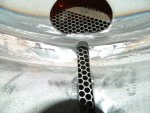

View attachment 782186

Now walk on the tire and make sure it will drop down below the ring mounting groove. If it doesn't you will need to let out some air from the tire. This step makes it so much easier to mount the ring.

View attachment 782188

Now your ready to install the ring. Make sure the rings gap is opposite the valve stem. With your foot, hold down on the rings end making sure it is in the ring groove. Using a hammer tap the rings outer edge, working it around the wheel until it goes down into the groove.

View attachment 782190 View attachment 782191 On my wheels I used a pry bar and a rubber mallet as I didn't want to mar my galvanized finish.

Once the ring is on, go around it again with the hammer making sure the ring is fully seated in the groove.

At this point I usually add a little bit of air to make sure the tire is held in place so the valve stem doesn't get moved out of position, then I place it in my tire cage to air up.

Now I know most people don't have a tire cage, so the best and safest way to air up a tire is to mount it back on the truck with the ring facing inwards towards the truck body. You only need two lug nuts to hold the wheel on.

Once the tire is fully seated and aired up to the proper pressure I remove it and lay the tire back down on the ground and remove the Schrader valve letting all the air out. This allows the inner-tube to fully relax so it does not create any over-lapping creases in the rubber which can cause a blow-out latter on when the wheel gets hot from driving. If the tire stays in contact with the rim after you let the air out, you can safely air the tire back up without the tire cage. If the tire does come loose from the rim you must put it back in the tire cage or remount it to the truck to safely re-inflate it.

I know many people don't go to all these measures to mount a tire, but it is one of the best ways to prevent any inner-tube issues later on. I know many truck tire shops use "tire gels" to mount the tires. I don't like using any "liquid" on my tires as I don't want to make it any easier to rust the wheels then is necessary.

The baby powder system has worked well for me and other mechanics for decades now. Plus it is easier to paint the wheels later on without having to wash off the tire goo. Just take a air blow gun and blow away the powder.

View attachment 782192