- 596

- 693

- 93

- Location

- Okinawa, Japan

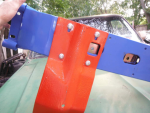

I'd get that repaired a the welding shop. Let them determine how to do it best. Personally I would weld a piece of strap across the crack on the flat edge and fill in the rest of the crack with a bead, then flap disk sand it smooth.I got the new flex plate installed and the transmission re-installed with original bolts. I also got the torque converter and new TC adaptor installed.

I was just cleaning the cross member to prepare it for re-installation when I came across a small hairline crack near one of the holes where the skid plate attaches. What do you think about that? Should I take it somewhere and have a bead welded over the crack or do you think I’ll be ok? I was hoping to get it done tonight but I’m waiting for your advice.

View attachment 838948View attachment 838949View attachment 838950View attachment 838951View attachment 838952

Good luck. Great work your doing... and fast.