-

Steel Soldiers now has a few new forums, read more about it at: New Munitions Forums!

Mav’s M1088A1 Conversion

- Thread starter Mavcaster

- Start date

More options

Who Replied?Ronmar

Well-known member

- 4,125

- 7,928

- 113

- Location

- Port angeles wa

There should be one stored in a holder on each can…Ah dang well I might have just enough cage bolts

- 8,052

- 20,421

- 113

- Location

- Charlotte NC

.Ah dang well I might have just enough cage bolts

The cage bolts should be in their holders on the spring brake chambers. If they aren't there, NAPA generally has them in stock. Two of the caging bolts on the M1088 are a little shorter than the others. The shock seems to be in the way with the bolts that are a little longer.

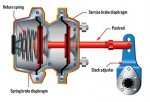

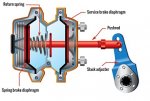

As far as what gets caged... The chambers that are "double size" for lack of a better description are the ones you need to "lock out" or cage. The only time you should cage your brakes are to move the truck - to release the brakes - if you have no air. Or if you are replacing the diaphragms...

If you are being towed by a wrecker or if you are on the end of a tow bar, don't cage the brakes. Not caging behind a towing vehicle gives you the additional stopping power of the towed vehicle. That is why there is a set of glad hands on the front of the truck...

Brake Applied

Brake Released (but Not Caged)

Last edited:

Yeah there is just one at each wheel but managed to scrounge up another 3 so left with one short. Just gonna try and drag the one wheel. Only need to go a few feet to get the cab back under the canopy while I start pulling apart the motor.

Duramax having a hard time getting her to slide.

Duramax having a hard time getting her to slide.

Last edited:

- 8,052

- 20,421

- 113

- Location

- Charlotte NC

.Yeah there is just one at each wheel but managed to scrounge up another 3 so left with one short. Just gonna try and drag the one wheel. Only need to go a few feet to get the cab back under the canopy while I start pulling apart the motor.

Duramax having a hard time getting her to slide.

You need just one bolt on each of the brake cans on the back

Last edited:

Oh haha well of course that was one of the ones I didn’t have caged. Anyways I finally got it back where I wanted it..

You need just one bolt on each of the brake cans on the back of the axles on the M1088

Ronmar

Well-known member

- 4,125

- 7,928

- 113

- Location

- Port angeles wa

Just remove the wheel on the one you cant cage or apply air to the front red gladhand, which is how a towing vehicle would release them…

or apply air to the front red gladhand, which is how a towing vehicle would release them…

Front emergency glad hand was the first thing that I tried but I think I have a stuck check valve because couldn’t get the system to build pressure from that.Just remove the wheel on the one you cant cageor apply air to the front red gladhand, which is how a towing vehicle would release them…

Gave me a reason to test 4 Low on the pickup anyway..

RRaulston

Well-known member

- 227

- 552

- 93

- Location

- Sahuarita, Arizona

Is this a complex job? I have 50psi cold then dropping to 18-20 @165. I had it to 180 once and full RPM was almost 40. Maybe I'm worried about nothing... My neighbor has a c7 in his LMTV and he has 20 PSI more than me across the board...They do all use the same oil pump. The listings I see show the same pump being used on 3116, 3126, and C7. So potentially yes the 3116 could have the older pump design and could be upgraded to the gerotor pump if needed or desired.

- 2,327

- 5,788

- 113

- Location

- Portland, OR

If this was my truck - I would pull the pan and check the pump condition. Given this numbers and the knowledge of the change in pump design..... I would have to see for myself.Is this a complex job? I have 50psi cold then dropping to 18-20 @165. I had it to 180 once and full RPM was almost 40. Maybe I'm worried about nothing... My neighbor has a c7 in his LMTV and he has 20 PSI more than me across the board...

Looks to be a fairly easy job.

- 575

- 1,100

- 93

- Location

- Cool, CA

If you end up needing a new fan clutch switch, one of our SS members sells them on e--y (callmecolt)

Maybe I misunderstood your post but looking back at the diagram you shared (and as GeneralDisorder also mentioned), it appears that every single can on the rear axles need to be caged in order to release parking brakes (8 total)? Just trying to clear that up for my future reference..

You need just one bolt on each of the brake cans on the back of the axles on the M1088

RRaulston

Well-known member

- 227

- 552

- 93

- Location

- Sahuarita, Arizona

I think I'm going to take it apart and inspect/change the pump in a few months when it warms up. First, I'm going to hard plumb an oil pressure gauge to verify my dash gauge. $785 for a new style CAT reman oil pump. Ouch. $250 for a Chinese pump.....nope..If this was my truck - I would pull the pan and check the pump condition. Given this numbers and the knowledge of the change in pump design..... I would have to see for myself.

Looks to be a fairly easy job.

Yeah I saw that price tag too…wow.I think I'm going to take it apart and inspect/change the pump in a few months when it warms up. First, I'm going to hard plumb an oil pressure gauge to verify my dash gauge. $785 for a new style CAT reman oil pump. Ouch. $250 for a Chinese pump.....nope..

- 8,052

- 20,421

- 113

- Location

- Charlotte NC

.Maybe I misunderstood your post but looking back at the diagram you shared (and as GeneralDisorder also mentioned), it appears that every single can on the rear axles need to be caged in order to release parking brakes (8 total)? Just trying to clear that up for my future reference.

@Mavcaster , just the cans on the back axle need to be caged IF you have no air in the brake system. Yessir, I may have mis-stated. There are a total of 8 cans on the two rear axles.

Instructions are in the TM.

TM-9-2320-366-10-2

Caging Process is extracted from that TM and is attached below.

Attachments

-

217.2 KB Views: 6

Trying to figure out why the parking brake will not disengage all of a sudden. Truck has been sitting for a few weeks while I've had the engine oil pan removed but just got that back on and couldn't move the truck. In the meantime, I did remove the 5th wheel air hookups (hoses still installed but now capped) could that be causing an issue? I would ultimately like to delete these lines altogether since I will be removing the 5th wheel.

- 8,052

- 20,421

- 113

- Location

- Charlotte NC

.Trying to figure out why the parking brake will not disengage all of a sudden. Truck has been sitting for a few weeks while I've had the engine oil pan removed but just got that back on and couldn't move the truck. In the meantime, I did remove the 5th wheel air hookups (hoses still installed but now capped) could that be causing an issue? I would ultimately like to delete these lines altogether since I will be removing the 5th wheel.

If it is anything like mine - if you have been getting rain - a drum might be seized to the brake shoes. Seems that several others here have had the same problem. If mine sits around in the rain for more than a week, it requires a "love tap" on the steel part of the brake shoe.

If you have re-plumbed air lines, all bets are off though.

Right yeah I know that problem well but brakes have been caged for the last few weeks while truck wasn’t running. The problem i’m having is park brake button will not release the brakes, air pressure is good front and rear but brake lines at each port below where the christmas tree sits are now disconnected. I assumed since these are trailer brake lines they wouldn’t effect truck brakes but could be wrong here..

If it is anything like mine - if you have been getting rain - a drum might be seized to the brake shoes. Seems that several others here have had the same problem. If mine sits around in the rain for more than a week, it requires a "love tap" on the steel part of the brake shoe.

If you have re-plumbed air lines, all bets are off though.

Park brake button is popping back out immediately that is.

Third From Texas

Well-known member

- 2,813

- 6,624

- 113

- Location

- Corpus Christi Texas

Hmmmm

I know that there is a procedure to delete the front towing air connections. And if down wrong....park brake won't release.

Make me wonder if it's a similar problem.

@Ronmar would know.

I know that there is a procedure to delete the front towing air connections. And if down wrong....park brake won't release.

Make me wonder if it's a similar problem.

@Ronmar would know.

- 112,476members

- 166,133threads

- 2,339,800posts

- 993online users