2deuce

Well-known member

- 1,486

- 160

- 63

- Location

- portland, oregon

Reading that some people fill the last filter with acetone and turn over the engine listening for the return flow to the tank, what if a thin lubricating oil was used in place of the acetone, or mixed with it? With the fuel pump pressurizing the IP, and pushing the oil into the IP, could I rock the engine back and forth slowly a small amount, then slowly turn it a full rotation?

Since I already turned over the engine a small amount would lube be better than only a solvent? It would have been better if I didn't turn the engine in the 1st place, but that is history.

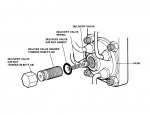

I have a picture in my mind how this pump works, that could easily be wrong, but if the plunger has moved without breaking so far, working it in lube oil, (if oil can get to it as it moves) would be similar to having the pump in hand and moving, or tapping on the plunger?

Originally I moved the engine clockwise only, so if the plunger is not broken it should move back counterclockwise without damage. At least that is my logic.

What do you guys think?

I'm back from camping and looking for a good shortcut. It appears to me that taking the pump off at this point, has much less benefit than if I did it in the 1st place. Messing up the timing is possible, and will leave me questions not knowing if it is the pump, or the timing if it won't run. If it won't run after this, I would know it's the pump for sure.

Thanks

Since I already turned over the engine a small amount would lube be better than only a solvent? It would have been better if I didn't turn the engine in the 1st place, but that is history.

I have a picture in my mind how this pump works, that could easily be wrong, but if the plunger has moved without breaking so far, working it in lube oil, (if oil can get to it as it moves) would be similar to having the pump in hand and moving, or tapping on the plunger?

Originally I moved the engine clockwise only, so if the plunger is not broken it should move back counterclockwise without damage. At least that is my logic.

What do you guys think?

I'm back from camping and looking for a good shortcut. It appears to me that taking the pump off at this point, has much less benefit than if I did it in the 1st place. Messing up the timing is possible, and will leave me questions not knowing if it is the pump, or the timing if it won't run. If it won't run after this, I would know it's the pump for sure.

Thanks