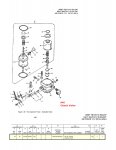

Nope, not correct. Essentially #6 and #11 are both referencing the same single check valve mounted under the clamp, right next to your oil pressure gage, just the first image isn't really accurate in it's orientation.

Item #45 is just a 90* brass NPT to Flare adapter, no check valve that I have ever seen, HOWEVER, the TM's only show the Bosch PSU injection pump which was used in the beginning on some Hollingsworth machines, but quickly replaced by the Ambac M-50 found on 80%+ of these machines.

It's been a while since I've worked on a PSU ( AKA P.O.S ) injection pump, so it is possible that the PSU had a check valve and they ditched it when Ambac took it over. But on the 5 or 6 PSU's I've seen I don't recall that fitting having a check valve built in.