I haven't posted much lately partly to being sick, but mostly I'm waiting on the machinist to finish some parts I'm having him make for me.

So I've been cleaning and sorting out parts. What to keep and what to throw away.

Here is a shift valve I cleaned today. As you can plainly see it is junk. The rust has eaten into the machined "land" so it will never seal properly again. The fluid will leak by causing strange shifts. Not good.

I ended up with half the valves in this valve body being trash. I was able to save the aluminum bodies though.

With all this down time I would love to start the second 303M build but I need the transmission holder. I am building a new holder that will handle over 1000 Ibs of weight. Again, the machinist is machining out the bore in the 2.5" X 2.5" block of steel that will get welded to the 1.25" thick x 6" x 8" plate.

Also the new Jib crane I'm building needs several items machined. So I'm stuck for now.

I still have four more transmissions to tear down, though I'm getting tired of cleaning parts right now.

I need a "hot tank" soon. Again it needs to be built by me. I will be making it out of stainless steel. I hate rust !!!!

So I'm cleaning parts and showing you all what to look for.

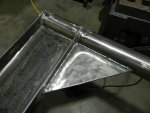

I am making a new oil pump pickup tube for my "gear" front pump. The gear pumps have the intake port standing straight up instead of at a 20-degree angle. The intake pipe is also 3/4" instead of 5/8" so an adapter will need to be welded on.

I cut up a junk oil pan housing to facilitate making the intake pipe.

There is one other thing I will show you today. The rear pump (not the reduction pump) on the 303M transmission does not make any pressure. It is dumped out. Why they did this I do not know. I'm trying to figure out how to adapt a civilian pump to the 303M transmission to increase fluid volume.

This is the 303M pump. You can see it is a small Gerotor style pump with a hole in the cover to drop the fluid. You can also see the outer ring is allowed to "float" in it's bore just like the reduction pump does. Very bad design.

This is a pump out of a 1955 Cadilliac HydraMatic.

It uses a crescent gear pump design. Extremely efficient for pressure systems.