Update on the swap. The trans had to come back out and be re-rebuilt. I drove the HMMWV less than 100 miles. Reverse started slipping. Felt literally like a badly slipping manual clutch. When you selected reverse it would barely make a shifting noise and barely move. I talked to Bowtie initially and they wanted us to provide line pressures and some other things for diagnosis which we did. After that they wanted me to return the trans to them for repair. Shipping would have been at least 600-700 round trip, then add the local shop charge for removal and another installation, and the time involved in shipping across country, we decided to repair ourselves and see what Bowtie could do to help on their end. Removal and inspection showed what my trans installer said to be a very rare problem. Apparently, the piston that engaged the reverse clutches was bad or incorrectly installed. This let to the reverse clutches being burned. Everything else in the trans was fine, but since the installer was technically rebuilding the trans and giving me a 3 year warranty he replaced all the clutches,etc. with his parts. We have had conference call with Bowtie yesterday. I am waiting to see today if they are willing to help out with any of the expenses.

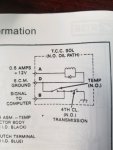

So...with all that said thrans is back in and works great. I still need to hook up the brake switch for the converter lockup. I bought a dual pole brake switch from a HMMWV with 4L80. The switch technically works but when I adjust the brake properly the pole for cancelling convertr lockup does not activate unless the brake lever is pushed so far the brakes would be locked. I cant find any adjustment on the switch.

https://www.ebay.com/itm/174542831485?chn=ps&_trkparms=ispr=1&amdata=enc:1fNBccByjRiGtwzKGjZIUlw83&norover=1&mkevt=1&mkrid=711-117182-37290-0&mkcid=2&itemid=174542831485&targetid=1644837436443&device=c&mktype=&googleloc=1013011&poi=&campaignid=16743749222&mkgroupid=138744546207&rlsatarget=pla-1644837436443&abcId=9300842&merchantid=101988484&gclid=CjwKCAjw0dKXBhBPEiwA2bmObdV8qomMFFcxkCkWT2RdpJmwwAEVOaPfEXYMshEwNuidvwjslyVCGhoC2dgQAvD_BwE

I'm getting frustrated with all that has happened and hoping to get some help without being told to use the search function. I have now decided to use a 24v relay tied to the standard brake switch to supply 12v to trans. My questions:

What wire can I splice into either under the hood or under the body to get a brake signal. Is there possibly a connection that I could simply us a "Y" packard adapter for the 24 volt signal. A "plug and play"location with an adapter I can make myself. I feel like I have the 12v side sorted.

Given that I am now going to use a relay. I thought about tying in the downshift/fan cutoff switch that is already installed on injector pump to disengage the torque converter when going wide open throttle. It seems like a good idea that yes it would work when going WOT but would also turn off fan everytime i hit the brake by backfeeding 24v. It would be great it that would work but can't figure out how to execute without negatives side effects.

As always any help appreciated.

Dan