- 2,789

- 6,666

- 113

- Location

- West greenwich/RI

Either way, E- stop or S1, killing power to the fuel solenoid, causing its plunger to spring forward, pushing the rack forward rotating the metering pump pins to the fuel-off position is the ONLY way to shut it off.

With it running, watch what the solenoid does when you turn S1 off. it should immediately push forward and push the rack lever all the way counter clockwise.

Also, if you were to remove the arm between the lever and solenoid, rotating it by hand counter clockwise until it hits the stop, the engine should immediately shut off.

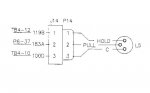

Your linkage could be binding, but still you should see no difference in performance between E- stop and S1 off, unless possibly a wiring problem with the 3 pin solenoid connector. IIRC it gets power from 2 locations, 1 while cranking and another while running. Perhaps there is a problem there, back feeding power when S1 is off, but not when the E-stop is hit.

Tell us what the solenoid does physically when s1 is turned off Vs. hitting the e-stop.

With it running, watch what the solenoid does when you turn S1 off. it should immediately push forward and push the rack lever all the way counter clockwise.

Also, if you were to remove the arm between the lever and solenoid, rotating it by hand counter clockwise until it hits the stop, the engine should immediately shut off.

Your linkage could be binding, but still you should see no difference in performance between E- stop and S1 off, unless possibly a wiring problem with the 3 pin solenoid connector. IIRC it gets power from 2 locations, 1 while cranking and another while running. Perhaps there is a problem there, back feeding power when S1 is off, but not when the E-stop is hit.

Tell us what the solenoid does physically when s1 is turned off Vs. hitting the e-stop.