I bought two A3's, one to hold and one to sell, and want to follow up on this (Allison 1545) subject. One of the A3's was purchased with a known tranny problem and I'll share what I have learned.

The truck that I purchased had a used tranny put into it and it does the same thing, fourth and reverse. The former owner's gamble with used did not pay off. I purchased the truck with a non working tranny in it and the original transmission was in a tote box in the bed, entirely disassembled. I ran across this thread and wish the link to the specifications was active...it's not...but I'll add what I have learned.

The military M35A3 was the only one to use the locking torque converter on the 545 series transmission. They added a 1 in front of it but that is not the same as an Allison 1000 series, an entirely different animal. Unlike the 545, there were only 5,600 A3's made so the availability of the 1545 transmission is extremely limited. It causes fear of this series...and rightly so.

I had not received the torque converter with the rest of the tranny in the box, I contacted the former owner. He located what he thought was the original torque converter. Because of the very good condition of all the gears and bearings on the original 1545 (in the box), I decided to rebuild (using an Allison factory trained technician for the tranny rebuild).

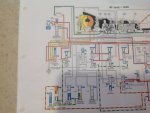

The Allison AT 1545 and the 545 share most components except the locking torque converter and valve body. The hub on the locking converter is larger however, so the non-locking and locking torque converter are NOT interchangeable. You cannot simply put a locking torque converter on a 545 and likewise, cannot put a 545 non-locking converter on a 1545 tranny. But a (very common) 545 with a non-locking converter will bolt right into place of the 1545. Unless one is on the highway all the time, this would be my choice if the 1545 is not rebuild-able.

The parts, clutches, steels, pistons in the 545 are the same as the 1545. You can get a gasket or rebuild kit for the 1545 or order the parts for the 545 and get the two larger seals for the 1545 separately. I had purchased the rebuild parts before I got the torque converter and had the entire rebuild completed when the torque converter arrived. Unlike the original tranny...this torque converter showed wear like one with higher miles. A torque converter rebuild shop said no problem until they say the input hub wear.

Looking at the Allison book of replacement hubs for the converter we discovered they were not available. My heart sank and I was considering a sleeve if the interior locking clutch was in good condition. There was no way to tell without splitting it, cutting the weld off.

Because of diesel popularity there has become an aftermarket industry where significant upgrades to torque converters can be had with billet hubs and additional upgraded clutches (going from one to three). That is the weakness of the original 1545 and probably why they were not more widely used. Of course at low speed, a locking torque converter would be entirely un-necessary.

I found two re-builders that were willing to take on the upgrades to my 1545 converter and I have just today sent it to Dacco in Tennessee (a Transtar company). I'll provide more information and cost when mine is returned. I was extremely happy with the quoted cost.

So to conclude, there are valid reasons to fear the automatics put into the A3, with the locking torque converter since there were only about 5600 of them made, but there are reasonable alternatives. For example: the original seals on the fourth piston hydraulic supply wear and won't put good pressure on the clutch pack but new PTFE seals allow about 20% higher locking pressures and don't degrade near as quickly. Likewise the rebuild on the torque converter hub is important because a seal leak can reduce the fourth clutch pressure. It has to be tight. If you rebuild the entire tranny and not the torque converter, you are only doing half the job.

While this is not about specifications of the 1545, I hope my information may help the next guy that is trying to decide if the A3 is a dog or a plum.