- 540

- 1,271

- 93

- Location

- Wapakoneta, Ohio

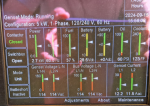

So i couldnt help myself and bought another 1030, inoperative. I filled with fluids but did not change filters, hooked up batteries, turned the disconnect on and it fired right up. 53hrs on the dcs and matches the analog meter. several bolts missing from the housing enclosure, but inside does not look to have been messed with. So closed the field and hooked up a space heater about 1400 watts. Ran well for a bit and then started pouring white smoke out exhaust and also will come out the dipstick. finger over the dipstick does not seem to be real pressure. i checked the TM and it says to check for Water in Fuel for white smoke. I came inside for a while to read and thought that made sense because the fuel cap was just hanging on. coming from North Carolina i know they have had a hurricane since this has probably been sitting there. So opened the fuel water seperator drain and very little came out. next decided to just run it for a while and as it ran the oil pressure kept getting lower and it started surging. i finally called it a night and will change out the filters tomorrow. Any other thoughts at this point are welcome. just getting into this thing. usually bolts missing indicate someone has been workikng on it, but i see no tool marks on top of the engine or fuel lines where an injector or anything would have been removed.