Unforgiven

New member

- 675

- 17

- 0

- Location

- Las Vegas, NV

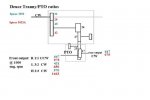

Is it possible to flip a single-output PTO shaft going to the winch to face rearward for a PTO hydraulic pump?

I am aware of the dual output PTO's but I can't find one for a reasonable price.

A future tranny swap that I really want to do will probably force me to use a hydraulic winch up front. But I would already have most of the plumbing done w/ a hydraulic pump already set up in the rear.

Can I disassemble the PTO & switch the front/rear cover&output? Can I simply rotate it 180 degrees on the tranny? Right now I don't foresee need for the winch, but do need a PTO hydraulic setup. So if I lose winch ability for a year or so I don't care.

I am aware of the dual output PTO's but I can't find one for a reasonable price.

A future tranny swap that I really want to do will probably force me to use a hydraulic winch up front. But I would already have most of the plumbing done w/ a hydraulic pump already set up in the rear.

Can I disassemble the PTO & switch the front/rear cover&output? Can I simply rotate it 180 degrees on the tranny? Right now I don't foresee need for the winch, but do need a PTO hydraulic setup. So if I lose winch ability for a year or so I don't care.