I went to NAPA today to return the Dexron transmission fluid and a few brass fittings. I picked up a Pressure Protection Valve, KN-31000 . I came up with a cleaned way to do the tap-in of the air line that feeds the air-ride seat. Here is the previous install:

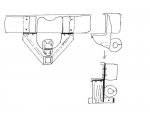

Here is the improved design:

After the install was complete i tested the system. Everything works fine. I also installed wire clamps to secure the CB radio antenna cable and the light feed wires. Then I adjusted the window on the driver's door again.

I took the ruck out for a ride on the Interstate to hear how the radio and speakers sounded on the road. It was a little hard to hear with the window down. I turned up the volume and I could hear the music enough to enjoy it.

As far as I am concerned the truck is done! If I think of anything else I will add it later.

Hope everybody enjoyed the ride! I will be starting a new thread for my latest project a M923 and M109 hybrid. Also known as my new camper project.

Waiting for vid of you starting her up, and taking for a short drive.

Waiting for vid of you starting her up, and taking for a short drive.