It sounds like the plunger guide may be cracked or striped and letting the guide get out 180 degrees. Ive had a couple that would run good, then on another startup run like crap and make the head super hot like yours. Temperatures would be almosy 400 degrees with no load. Sometimes the guide will strip and not hold the plunger in the right position throwing the injector timing off.Couple of things... Don't trust the onboard Panel Hz meter. The sender or gauge itself can go bad. I would use a Kill-A-Watt meter, or the like, to verify all Hz & Voltage readings.

As you indicated the Control Box has been replaced & the Mfg Placard is probably associated with the Genset it was taken off of. So, the date stamped on it would be meaningless. From the looks of it I would say your unit is in the range of the early to mid 80's.

I must confess I have limited mechanical knowledge with the "Injection Pump & injectors". I am fortunate that all my gensets start reliably & run within parameters so far... knock on wood! Although I've familiarized myself with the IJ pump & injectors inner workings from several excellent SS threads where they dive deep into the IJ pump rebuilds, etc. and would not fear "hands on troubleshooting" them on my gensets.

Thus, I cannot determine if your present generator's sporadic engine issues are caused by the injectors, IJ pump or....? Perhaps someone @Ray70 or @jamawieb can better direct you towards troubleshooting tips to pinpoint the engine bogging down & RPM issues you are experiencing.

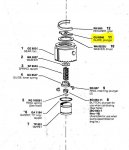

Ray70 does an excellent job in rebuilding the injectors but i would time the pump first before moving forward. Then if its off time pull and check the guide.