- 1,579

- 556

- 113

- Location

- Greenback, TN

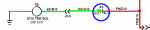

Working on a Sheriff's Dept gen set, MEP-003A. Has been sitting for years. Engine running now and sounds good but there are issues. The voltage and phase selection switch will not turn. Feel the spring load but the contacts do not jump to new positions. It seems the issue is mechanical and not in the electrical contacts, we hope. We have lubed the mechanical shaft parts in the front on the switch shaft, best we can get to it. Any suggestions? Is this a common failure? Changing that switch would be a nightmare.

There's no indication of AC output. There is DC output, mid green on the gauge. We haven't even started troubleshooting until the big switch works.

Other small issue is no 'start signal' to the starter solenoid. A jumper from 24v to the solenoid coil contact allows it to start (starting control switch held to "start' at same time).

Is that voltage/phase switch serviceable at all?

There's no indication of AC output. There is DC output, mid green on the gauge. We haven't even started troubleshooting until the big switch works.

Other small issue is no 'start signal' to the starter solenoid. A jumper from 24v to the solenoid coil contact allows it to start (starting control switch held to "start' at same time).

Is that voltage/phase switch serviceable at all?

Last edited: