- 3,765

- 3,845

- 113

- Location

- Brooklyn, NY

Don’t forget that you can always use a GPS program like Waze on your cell phone as a speedometer so you do not need a working speedometer in the vehicle if you have a good cell phone.

Steel Soldiers now has a few new forums, read more about it at: New Munitions Forums!

Actually I have a 80 mph electric HMMWV speedometer to install. I already put in the sending unit and the wiring while doing the transmission swap. I have to fix the bezel then paint it before I install it. That said, the rear view camera I am installing also has a GPS/dash cam etc., built in. And I am mounting the TCU so I can see the display and it also displays the speed.Don’t forget that you can always use a GPS program like Waze on your cell phone as a speedometer so you do not need a working speedometer in the vehicle if you have a good cell phone.

There are many GPS speedometers available that fit right into the dash (3 3/8"/ 85MM) and most can run on 24V, they are very accurate and care not about the gearing, tires etc. one of the first mods I have done on both of my M998sActually I have a 80 mph electric HMMWV speedometer to install. I already put in the sending unit and the wiring while doing the transmission swap. I have to fix the bezel then paint it before I install it. That said, the rear view camera I am installing also has a GPS/dash cam etc., built in. And I am mounting the TCU so I can see the display and it also displays the speed.

Thanks for the info but I am not really concerned about the overall accuracy of the speedometer but I suspect it will be pretty close. More important to me is the look of originality even though it isn't original it will appear to belong more than a GPS digital readout style.There are many GPS speedometers available that fit right into the dash (3 3/8"/ 85MM) and most can run on 24V, they are very accurate and care not about the gearing, tires etc. one of the first mods I have done on both of my M998s

I never considered a digital readout, all mine are analog.Thanks for the info but I am not really concerned about the overall accuracy of the speedometer but I suspect it will be pretty close. More important to me is the look of originality even though it isn't original it will appear to belong more than a GPS digital readout style.

Very nice, if I were going Duramax that would be a great option. Thanks for sharing.I never considered a digital readout, all mine are analog.

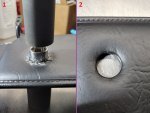

View attachment 853834

I picked this one for the Duramax conversion because it had the turn signal and high beam indicators in it.

I drove it home from the shop where I did the transmission swap and I will say it is quieter in the cab. As Action said, it is quieter due to the lower RPM of the engine.I am curious if the 4 speed will make it noticeable quieter in the cab. I do not have a need for the performance of a 4 speed, but I would consider it if the noise reduction is substantial. I underestimated how much louder my truck would become when I replaced the soft doors and top with X Doors and an armored roof (it was the cheapest route at the time).

Thanks for the information, I will give it a shot.Wipers.....

Remove bolts holding wiper motor to w/s frame.

Pull out as much as you can.

Remove nut holding linkage to the motor.

Turn wipers by hand to other side of w/s.

Put linkage back on motor with nut.

Put motor back on w/s frame.

The linkage only fits on motor in 2 positions, 180 degrees apart.

If you have tach on w/s frame, it will be easier to remove it.

The wiper on the driver side is almost in front of the dash cam and in my view more than I like so I am going to try it the other way. I will note the pass side mirror after i try it however I have added the rear view camera to act like a rear view mirror so I am hoping to use the pass side mirror less.For the wipers, mine started out on that side, then I switched it. After a few months I switched it back.

For me, having it parked on the driver's side helped keep the water running straight down the windshield out of my line of sight slightly longer due to the amount of Rain-X I use. That and parking it on the passenger side put it in line with the passenger side mirror.

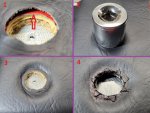

Not even going to try to fix that brass tube that is split. It is epoxied into the pump and is not right. I will replace it one way or the other to fix it.Springer…

That pipe, unless it is made of Aluminum, should be easy to solder.

The water pump itself, can be repaired with aftermarket 24 V pumps as per Juanprado