Thought I would begin my first post here about a super ambitious project that I’m working on. I have worked out the details, mostly, but I’m sure I’m going to need to tips along the way. For this build I will be merging two unique military trucks together. This story begins some time ago, when I obtained a Man Kat 8x8 truck from the mighty state of Texas. Sight unseen, it arrive to me here in Newnan, Ga. I originally had high hopes of some kind of original restoration of this German made transport truck, but once I saw it in person, I came to the realization, that “Plan A” whuten gonna happen.

The Texas sun, heat and most likely, corrosive salt water had literally dissoved most of the steel hydraulic fittings and a ton of other essential fluid carrying components. The ZF transmission was toast, with the rear of that ten speed monster completely removed. Mechanically everything else seemed ok, axles, driveshafts, wheels, brakes were all still there and intact.

Since Man doesn’t sell any truck parts here in the US, I knew I wasn’t going to be restoring the German engine and transmission. So began the quest for what I called, “The Donor”. I needed a super heavy duty truck, with a strong transmission, transfer case, and engine! Preferably all together.

My initial search began with what was typical for a HEMTT, historically speaking, older, I.e. mechanical would probably be best, since the ManKat was an early 80s military truck. I needed to reporter this 8x8 with an American power pack! I looked for months and months. Then, the miracle happened…

As I mentioned before, I live in Newnan, GA. Well right up the road from me is Peachtree City, GA. Home to Falcon Field Airport and also home to numerous aircraft parts, service, and manufacturing facilities. And it just so happened that the decent sized helicopter restoration and rebuild facility was needing to sell a couple of ex-Navy Ameritek CF4000L , airport firetrucks from their back yard/helipad. When I say helicopter rebuild facility, I do mean military helicopters, ex presidential helicopters. They did turbine and body rebuilds there. I got an awesome tour of the place when I first responded to the Facebook mk listing. Got to see GW Bush helicopter being refurbed for his presidential library. Didn’t realize that those helicopters has emp counter measures, as well as radar resistant paint. Awesome sauce.

In any case. I after taking a very close look at the firetrucks, engine and drivetrain, I realized that these trucks were gonna be the donors for my 8x8. Well at least, one of them was...

But, there was a catch, I had to buy both firetrucks. The Good: they would deliver to my shop with their lowboy and they were only $10,000. The Bad: only one truck ran, the other one had a blown tire, and the plastic bucket they had used to cover the vertically oriented exhaust pipe , had failed, thus, the engine had soaked in a lot of water for quite some time and rusted the cylinders and other components before they realized what happened.

, had failed, thus, the engine had soaked in a lot of water for quite some time and rusted the cylinders and other components before they realized what happened.

I had exactly two weeks to scrape up $10,000 from zero, ouch. A lot of people wanted these firetrucks, but I was first on the scene, and very local, for whatever that’s worth in any sale. I liquidated some equipment projects that I wasn’t going to finish, a MASH unit turbo shaft engine, a Cnc that I built and anything else that wasn’t bolted down, etc, etc. And at the amen hour I had $10,000 in cash in my hand and a grin that you couldn’t slap off my face, and went to do the deal! As a bonus, they had a huge box of manuals to go with the firetrucks. These were nicely, sorted and labeled.

Just to provide a little background on these Ameritek firetrucks, so you can see why they would be perfect donors for the Man Kat 8x8. They are rear drive trucks, with a Detroit Diesel 400hp, 6v92TA engine, turbo’d and supercharged, paired to an 5 speed automatic Allison HT740 transmission, Eaton locker 20/40 ton axels. These Navy firetrucks were low hours of course. Now for the details of ”the plan”…

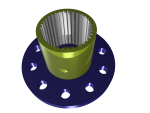

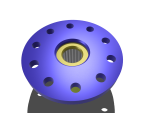

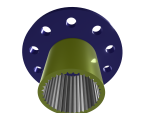

The PLAN. Or plan B, I should say. Of which, Phase 1 is now complete! The simple version. Swap the engine, transmission, transfer case, and air brakes system from the Amertek firetruck onto and into the Man Kat 8x8. Now instead of a cabover, non-turbo Man v10 D2840 with 10 speed manual transmission, I will have a an all American, rear mounted, Detroit DKesey supercharged engine, with a 5 speed automatic Allison trans and Eaton 4x4 transfer case. That is where the American mechanical components stop. And everything downstream from the transfer case will be all Man truck equipment, driveshafts, axels, wheels. Phase 1 was to remove the ZF transmission/transfer case from the 8x8. Then disconnect and remove the ransfer case from the firetruck. Both of those have now been completed. Phase 2, will be to remove the transfer case universal joint mounting plates from the ZF transmission and design a custom metal union so that the driveshafts coming from the 8x8 axels will marry up to the Eaton transfer case with that one 1-1/4” king nut, the Man has like 12 fine thread bolts on the U-joint plate. I have already designed some potential union arrangements in Shapr3d. Once this is done, the Eaton transfer case will be lowered down between the frame rails of the 8x8, to approximately the same position as the transfer case of the ZF trans. The new transfer case will be placed reverse of the old one, with the transmission driveshaft going backwards to the soon to be rear mounted 6V92TA engine. i Plan to move the air brakes over from the firetruck as well, and just make new mounts for the air brake cylinders, and marry them up to the mechanical actuator brake arms of the 8x8. Should work the same way, I think. And lastly, as much as I wanted to keep the Man 8x8 cab, I think I will just transfer the whole cab from the Amertek firetruck onto the 8x8 chassis for ease of electrical and mechanical connection. It’s all aluminum, has more seats and more room.

I will be post regular updates from here as this project moves forward. Any tips and suggestons are more than welcome. It’s gonna be awesome when it’s finished.

The Texas sun, heat and most likely, corrosive salt water had literally dissoved most of the steel hydraulic fittings and a ton of other essential fluid carrying components. The ZF transmission was toast, with the rear of that ten speed monster completely removed. Mechanically everything else seemed ok, axles, driveshafts, wheels, brakes were all still there and intact.

Since Man doesn’t sell any truck parts here in the US, I knew I wasn’t going to be restoring the German engine and transmission. So began the quest for what I called, “The Donor”. I needed a super heavy duty truck, with a strong transmission, transfer case, and engine! Preferably all together.

My initial search began with what was typical for a HEMTT, historically speaking, older, I.e. mechanical would probably be best, since the ManKat was an early 80s military truck. I needed to reporter this 8x8 with an American power pack! I looked for months and months. Then, the miracle happened…

As I mentioned before, I live in Newnan, GA. Well right up the road from me is Peachtree City, GA. Home to Falcon Field Airport and also home to numerous aircraft parts, service, and manufacturing facilities. And it just so happened that the decent sized helicopter restoration and rebuild facility was needing to sell a couple of ex-Navy Ameritek CF4000L , airport firetrucks from their back yard/helipad. When I say helicopter rebuild facility, I do mean military helicopters, ex presidential helicopters. They did turbine and body rebuilds there. I got an awesome tour of the place when I first responded to the Facebook mk listing. Got to see GW Bush helicopter being refurbed for his presidential library. Didn’t realize that those helicopters has emp counter measures, as well as radar resistant paint. Awesome sauce.

In any case. I after taking a very close look at the firetrucks, engine and drivetrain, I realized that these trucks were gonna be the donors for my 8x8. Well at least, one of them was...

But, there was a catch, I had to buy both firetrucks. The Good: they would deliver to my shop with their lowboy and they were only $10,000. The Bad: only one truck ran, the other one had a blown tire, and the plastic bucket they had used to cover the vertically oriented exhaust pipe

I had exactly two weeks to scrape up $10,000 from zero, ouch. A lot of people wanted these firetrucks, but I was first on the scene, and very local, for whatever that’s worth in any sale. I liquidated some equipment projects that I wasn’t going to finish, a MASH unit turbo shaft engine, a Cnc that I built and anything else that wasn’t bolted down, etc, etc. And at the amen hour I had $10,000 in cash in my hand and a grin that you couldn’t slap off my face, and went to do the deal! As a bonus, they had a huge box of manuals to go with the firetrucks. These were nicely, sorted and labeled.

Just to provide a little background on these Ameritek firetrucks, so you can see why they would be perfect donors for the Man Kat 8x8. They are rear drive trucks, with a Detroit Diesel 400hp, 6v92TA engine, turbo’d and supercharged, paired to an 5 speed automatic Allison HT740 transmission, Eaton locker 20/40 ton axels. These Navy firetrucks were low hours of course. Now for the details of ”the plan”…

The PLAN. Or plan B, I should say. Of which, Phase 1 is now complete! The simple version. Swap the engine, transmission, transfer case, and air brakes system from the Amertek firetruck onto and into the Man Kat 8x8. Now instead of a cabover, non-turbo Man v10 D2840 with 10 speed manual transmission, I will have a an all American, rear mounted, Detroit DKesey supercharged engine, with a 5 speed automatic Allison trans and Eaton 4x4 transfer case. That is where the American mechanical components stop. And everything downstream from the transfer case will be all Man truck equipment, driveshafts, axels, wheels. Phase 1 was to remove the ZF transmission/transfer case from the 8x8. Then disconnect and remove the ransfer case from the firetruck. Both of those have now been completed. Phase 2, will be to remove the transfer case universal joint mounting plates from the ZF transmission and design a custom metal union so that the driveshafts coming from the 8x8 axels will marry up to the Eaton transfer case with that one 1-1/4” king nut, the Man has like 12 fine thread bolts on the U-joint plate. I have already designed some potential union arrangements in Shapr3d. Once this is done, the Eaton transfer case will be lowered down between the frame rails of the 8x8, to approximately the same position as the transfer case of the ZF trans. The new transfer case will be placed reverse of the old one, with the transmission driveshaft going backwards to the soon to be rear mounted 6V92TA engine. i Plan to move the air brakes over from the firetruck as well, and just make new mounts for the air brake cylinders, and marry them up to the mechanical actuator brake arms of the 8x8. Should work the same way, I think. And lastly, as much as I wanted to keep the Man 8x8 cab, I think I will just transfer the whole cab from the Amertek firetruck onto the 8x8 chassis for ease of electrical and mechanical connection. It’s all aluminum, has more seats and more room.

I will be post regular updates from here as this project moves forward. Any tips and suggestons are more than welcome. It’s gonna be awesome when it’s finished.

Attachments

-

4.1 MB Views: 72

-

3.1 MB Views: 75

-

2.4 MB Views: 71

-

2 MB Views: 68

-

1.4 MB Views: 81

-

15.5 MB Views: 87

-

5.7 MB Views: 96

-

5.5 MB Views: 91

-

5.6 MB Views: 87

-

5.7 MB Views: 86

-

5.9 MB Views: 86

-

8.7 MB Views: 85