Lindsaym151

Member

- 666

- 12

- 18

- Location

- Eustis,FL.

Thank you! It will be a couple of days before I post again ! getting busy with work and getting the Southern rally set up for Feb2018!!

Steel Soldiers now has a few new forums, read more about it at: New Munitions Forums!

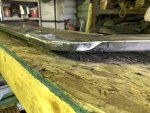

OK, had a day come to me, worked on the front floor pan and the riser between the gas compartment.

OK, had a day come to me, worked on the front floor pan and the riser between the gas compartment.

Hey everyone,

Hey everyone,

Today we managed to get the drivers side panel completed!

Today we managed to get the drivers side panel completed!We get it, advertisements are annoying!

Sure, ad-blocking software does a great job at blocking ads, but it also blocks useful features of our website like our supporting vendors. Their ads help keep Steel Soldiers going. Please consider disabling your ad blockers for the site. Thanks!