- 10,350

- 75

- 48

- Location

- Meadows of Dan, Virginia

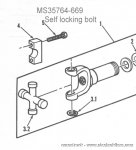

After reading the thread by Russ and his drive shaft "incident", I started to look at the xm757 and it uses self locking bolts as shown in the images below.

My question is, what part or feature of the bolt makes it "self locking"? It screws easily all the way in and uses apparently ordinary 1/2-20 threads. There is a slight under score (?) on the bottom side of the head so that the head rests flat.

The part number is MS35764-669. The tightening torque from the TM is 90 to 100 ft-lb, which is lower than the recommended value from tables (130 ft-lb).

Any insight here would be appreciated.

Any thoughts on using safety wire type bolts?

My question is, what part or feature of the bolt makes it "self locking"? It screws easily all the way in and uses apparently ordinary 1/2-20 threads. There is a slight under score (?) on the bottom side of the head so that the head rests flat.

The part number is MS35764-669. The tightening torque from the TM is 90 to 100 ft-lb, which is lower than the recommended value from tables (130 ft-lb).

Any insight here would be appreciated.

Any thoughts on using safety wire type bolts?

Attachments

-

85 KB Views: 483

-

80.1 KB Views: 481