- 333

- 262

- 63

- Location

- Denver, Colorado

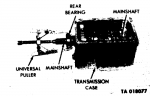

What you asked is correct on removing the mainshaft, you just need to keep an eye out for the non-caged bearings falling out the back of the input shaft as you remove the mainshaft. Regarding 2nd gear, Gringeltaube has recommended grinding oil channels into the shoulder adjacent to the 2nd gear bore, so more lube gets to the shaft... Hey Gerhard, you got a pic of that you can share with us again?No metal in the sump. This may have been this way for a while, as I have only driven it down the highway twice, and its always on a gravel (good areas) road or worse, so I may have not noticed. If I can get the mainshaft rear bearing out, then the mainshaft should move to the rear, lifting the front up and out, and the whole assembly will come out? If that works, I should be able to replace the mainshaft and second gear without pulling the transmission. Guyfang has generously posted the TM's which has the tolerances. BTW the spell check must be a old sailor. its changed every "mainshaft" to mainsheet.

If you do have to replace the mainshaft, don't forget that great deal Boyce has on them; https://www.ebay.com/itm/Military-T...245080&hash=item28204263dd:g:KCYAAMXQxzZRfKbP