I have enjoyed this thread. Please review my plan and tell me what you think - I am still going thru the MK23 to insure it's fitness for long-term use. I will be at least part of the time living in this in all four seasons in polar to equatorial environments.

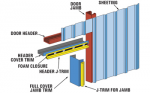

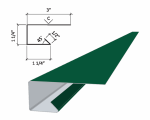

I am starting with a Mk23 7ton. My plan (which may change as this thread all sinks in) was to use 2x2 14 gauge mild steel tubing and then FRP panels with 2 inch foam cores, with plywood stiffeners added to the roof panel. To explain: use the tube as a frame, notch the inside of the FRP panels and insert them into the frame with sikaflex and overlay the corners on the outside with angle pieces of probably aluminum, reinforcing the sikaflex with rivets to the tube frame thru the aluminum, FRP, and into the tube frame. There is a company in Spokane that makes the panels in any length width you want and they make a floor panel too. Mainly used for commercial trucking and refrigerator trucks. they say the panels are structural all by them selves and my square tube frame is not needed - my reason is impact damage, i.e. tree branches hitting the corners. they also make repair panels that can be grafted in with standard fiberglass skills.

To maybe help make clear: make a box insert the panels into the sides of box using appropriate tools cut in windows, door and vents as needed on site using hot knife and trimmed to fit with treated wood to internally frame between the panels for openings sealed with layer of fiberglass. The center material below would be the roof. The exterior finish can be spec.'d to your needs I plan on coating the outside with spray on epoxy bedliner over a primed fiberglass surface, the interior can also be spec.'d to work with what you want, thinking clear resin over the plywood. The thickness of the plywood sheeting is also at your spec.

I am in the middle of Wyoming, everything is a long way away, so driving the Mk to Spokane to pick up the panels seems like the closest thing for me (860+ miles one way). Steel is a real expense here (cost to transport), will probably have to drive to Denver (250 miles +/-) to get a decent deal on it still looking at that. 150 miles away is like just the next town over around here so my transport distances are extreme compared to most in this thread.

picture of product, looking at the two panels on the left. albeit in different thickness.

Company's Webpage:

Fiber-tech manufactures composite panels & fiberglass reinforced panels for all markets & applications. Request a quote or contact us to learn more.

www.fiber-tech.net