With the help of red and another friend, we removed the hard top and seats from the truck, and these crazy guys found out what it would be like to drive a deuce like a boat: standing up!

View attachment 616576 View attachment 616577 View attachment 616578

View attachment 616576 View attachment 616577 View attachment 616578

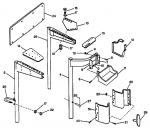

Before the gun ring goes on I want to more or less restore the hardtop / cab. I do not particularly want to remove the gun ring once it is in place.

I'm currently trying to decide if I want to go to all the hassle of pulling the cab free of the truck to add heat reflective material/insulation to the engine side of the firewall and the underneath side of the cab. I want to "do it right" but I'm greatly leaning to just adding it to the easy to access transmission and transfer case tunnel only and not removing the whole front body of the truck (cab, fenders, hood, grill, and engine side panels). Going to that extent I'd feel like I might as well go the full restoration route but I'm not to that point yet. I have a personal goal that my truck must be ready and operational for every 4th of July. That gives me just under 3 months, and I've still got a cast on my left arm for at least two more weeks.

Also, I still need to decide on the reflective material, insulation and/or sound deadening I want to buy. I'm liking the Boom Mat products but there's a lot of options and, honestly, they all sort of seem the same.

I want to put as much as I can of that sound deadening and insulation material inside the cab (back and top) - especially before I install the cab reinforcement plate.

Speaking of the reinforcement plate, I was considering installing it with nutserts instead of the supplied rivets. I don’t know how much torque the nutserts can handle but it'd make the plate fully removable for future needs (wiring, repair, etc)! The nutserts look like they'd be physically larger so maybe not as many could be used? I have zero intention of shooting a .50 caliber gun from the truck. .30 maybe, but never .50 (I may go with the .50 dummy gun though!).

Nutsert info video:

https://www.youtube.com/watch?v=sz2yZNqGNqo