Ok, well sorry I have not been putting up any pics... the other day the camera on my phone died... I will have to take some when I get a chance but today I did the setup, break in/test drive and can say that it works well. I definately made some mistakes. the guide said to use a 300psi gauge if possible (my cheapo kit came with a 500psi kit soooo... I put the 300psi compression gauge on there. My pressure readings were all off, turns out "psi is psi" is not really true after all! Anyhow, once that was figured out I redid my readings and needed to slack my tv cable by about .25", and then I was able to test it.

1,2,3 were great but it was raining and I live in the curves so it was hard finding a spot to try and get into OD. At first I assumed the cable was still to tight so I loosened it just a touch (watching the gauge) to something still safe but it proved to be obviously too loose so I put it back where it was and went off in search of a straighter highway.

Finally hit some nice straights and OD was achieved, tested the lockup relay which worked fine (nice to be able to here the relay click every brake press as confirmation the relay is working.

Some things I have noticed, the transmission is nice, my motor is weak. O was able to hit OD on a slight incline on a straightaway and I was going about 60 at 2100ish rpms but that was about all my 6.2 could muster. Down the same straight away going at a slight decline I was at 65 at about 2400rpms which was great... that is as fast as I ever want to go in this thing. After this and coming home I was able to have it engage in OD at some lower speeds, 40 at 1400rpms on a downhill was amazing! This was not happening when I first tried it so I think really getting it up to speed and shifting was needed and I should have done that before resetting the TV cable. Chris at BO stayed in contact with me even though it is Xmas eve and all and gave me some pointers through this.

Trans temp gauge works as expected, I did see it warm up to 160 but have not heard the fan come on... yet, it is cold out and I am sure I will hear it when it needs it. Pics when I get back.

I filled up with fuel and will post mileage results when I return in a week or so. Thanks you guys for the advice on getting all the proper parts to do this!

Sharecropper I think you are going to utilize 4th a lot more than me with the more powerful motor. Will be interested to hear your experience when you get it all on the road.

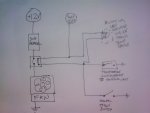

I sourced a big two pole switch and installed it to solve this problem as well as got the run to the front done along with a blinky red led both at the switch and in the cab to remind me that winch switch is on. The switch and wires sit just under the battery tray leaving more room for when I get the second tray back in place. (thinking 2nd tray will be used for air bag air compressor and heat exchanger/water pump for hot water etc...)

I sourced a big two pole switch and installed it to solve this problem as well as got the run to the front done along with a blinky red led both at the switch and in the cab to remind me that winch switch is on. The switch and wires sit just under the battery tray leaving more room for when I get the second tray back in place. (thinking 2nd tray will be used for air bag air compressor and heat exchanger/water pump for hot water etc...)