- 4,330

- 1,936

- 113

- Location

- Edmond, Oklahoma

Steel Soldiers now has a few new forums, read more about it at: New Munitions Forums!

Appears to only need a bit more clearance. Wondering if there is a way to slightly reform the switch cover while it is screwed on up tight... like put something round (A phillips screwdriver?) on the offending edge of cover there where the screw hits & give it a slight whack with a hammer to form a slight dent in cover where it hits the offending screw. Of course, I don't know what is under the cover in that area of the Switch innerds...

Will for sure try adjusting it first before replacement.SO lets go back to S7 for a minute. You were 99% of the way there a few days ago, but I think you got a little mixed up with the testing of S7 both hot and cold. Anyway... before you fight things any further and replace the switch, try giving it a tiny bit of adjustment outward ( unscrew ) the adjustment like 1/4 to 1/2 turn. I see no reason to fight yourself trying to replace it. Its probably just barely on the fringe of Out of adjustment.

I thought about that, but don't know what's under the cover in that area and can't find any pictures that show it.Appears to only need a bit more clearance. Wondering if there is a way to slightly reform the switch cover while it is screwed on up tight... like put something round (A phillips screwdriver?) on the offending edge of cover there where the screw hits & give it a slight whack with a hammer to form a slight dent in cover where it hits the offending screw. Of course, I don't know what is under the cover in that area of the Switch innerds...

Yep the M116A2 trailer tarps apparently dried up in the market. I did purchase a new one a few years ago from a SS member that was new & then affordable.The issue tarps don’t exist anymore for these.

Will keep the bows and rig up an enclosure for it.

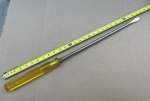

Well just so happens my recently aquired #5 Genset didn't come with a cover over S7 start switch. So I snapped a picture for you to view whats underneath cover in that area.I thought about that, but don't know what's under the cover in that area and can't find any pictures that show it.

Hopefully the adjustment works and I will not have to find out.

As much as this this vibrates, will probably be more for me.Good pictures!

If I remember right, I had to adjust the S7, 2-3 times to get it right. Take your time and test it 20 times before putting the cover back on.

So worked on this for the last two hours.SO lets go back to S7 for a minute. You were 99% of the way there a few days ago, but I think you got a little mixed up with the testing of S7 both hot and cold. Anyway... before you fight things any further and replace the switch, try giving it a tiny bit of adjustment outward ( unscrew ) the adjustment like 1/4 to 1/2 turn. I see no reason to fight yourself trying to replace it. Its probably just barely on the fringe of Out of adjustment.

getting that cover on can be a bear. I think on my 003, I had to actually grind off some of the adjustment screw(shorten it) to get it to fit.Well just so happens my recently aquired #5 Genset didn't come with a cover over S7 start switch. So I snapped a picture for you to view whats underneath cover in that area.

If you select the photo & zoom up it shows the clearance more clearly to the lift solenoid screw you are having the interference with. Also, if you had the oil cannister taken off, perhaps it might allow you some additional room to work a slight deflection crease in the switch cover to obtain the necessary clearance.

Of course, I really don't have any reference to how close it comes to the switch contact arm when cover is screwed down tight in place. It might only be 1/8" to 1/4" of clearance... Though looking at your 1st photo in your post #159 above, it looks like the interference you are experiencing is off to the side of the cover so that area underneath cover might be somewhat open.

OKOnce you're satisfied with the hot start, make sure you go back and verify that the starter won't engage if you try to crank while its running.

The TM will give you the specifics, but the interrupt switch is supposed to break the circuit at somewhere around 600 RPM ( IIRC ) so you can hold in the crank position while it builds oil pressure to close that circuit.

Just need to verify you don't adjust too far out and mess up the "disengage" side of things.....