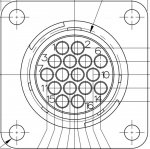

Chilbun, as you've already gathered, the general consensus here is to not by-pass the P7/J7 connector or jump around any of the perspective pins in that connector. But we're not there with you looking at your particular unit. If that 16-pin cannon plug is damaged beyond repair as you say it is, the next step would be to replace it or the individual pins that need replacement. The parts are all available on-line. It will require a couple of tools. One for removing the individual pins from the connector. Another for crimping the replacement pins to the wires. It will also require some patience as mentioned above. Use the information that has been provided in this thread to locate the wires into the correct place. These cannon plugs have little locating notches in them. When the notches are lined up, the connectors can be pushed together and the ring can be rotated to secure both halves of the connectors together. (See the diagram above to see the notches)