Jacob2027

Member

- 65

- 29

- 18

- Location

- Southeast alaska

Lol no problem.Damn, that was dumb. I thought I was on the "engine running to fast post". Sorry guys.

Steel Soldiers now has a few new forums, read more about it at: New Munitions Forums!

Lol no problem.Damn, that was dumb. I thought I was on the "engine running to fast post". Sorry guys.

View attachment 797591

Used as a logging truck for many years. Toyo 10.00r20s on the back with good tread and split rims. Military 9.00r20s on the front on split rims. Need to change to the 10.00r20. Where does everyone here go for tires?

Air pressure should be under 120 psi, brake fluid pressure could be over 3000. The brake boost comes from a four inch diameter air piston pushing on a .5 inch diameter brake fluid piston, about a 16 to 1 ratio. When it's not working, you have to make all the pressure with just the brake pedal. HTH.That guide is awesome. Was actually just looking for that info. I can understand wanting to get away from hardline kits. I was wondering if I could use nylon airbrake line on the brake circuit. Considering dot 5 is non corrisive and non reactive. The pressure shouldn't be above that ove the air master line I wouldn't think. Have you ever tried or considered this?

NO, you cannot! Nylon airbrake line is rated for around 150 PSI max. The hydraulic side of the brakes operate at around 2,000 PSI or more.That guide is awesome. Was actually just looking for that info. I can understand wanting to get away from hardline kits. I was wondering if I could use nylon airbrake line on the brake circuit. Considering dot 5 is non corrisive and non reactive. The pressure shouldn't be above that ove the air master line I wouldn't think. Have you ever tried or considered this?

Like SCSG-G4 said, the brake booster uses air pressure to magnify the brake fluid pressure, increasing it many times over what the air pressure is.Air pressure should be under 120 psi, brake fluid pressure could be over 3000. The brake boost comes from a four inch diameter air piston pushing on a .5 inch diameter brake fluid piston, about a 16 to 1 ratio. When it's not working, you have to make all the pressure with just the brake pedal. HTH.

I see. I hadn't thought about that fact. Apparently even regular hydaulic brakes have a ton of psi but it doesn't seem like it when doing pedal based bleeding... Thanks for the info.NO, you cannot! Nylon airbrake line is rated for around 150 PSI max. The hydraulic side of the brakes operate at around 2,000 PSI or more.

Like SCSG-G4 said, the brake booster uses air pressure to magnify the brake fluid pressure, increasing it many times over what the air pressure is.

I have all tms I could find downloaded related to operation tm9-2320-209-10, lube lo9-2320-209-12, maint. Tm9-2320-209-20, and parts tm9-2320-209-20pJacob I do have one suggestion for you and that is to get a set of Technical Manuals for your truck or they can be found on this website for free! When you talking about your truck it sounds like your doing way more poking around rather haphazardly looking for some result? If you have the the TMs you will be able to research the issues, then examine how to fix them and the TMs will take you step by step through all the steps to take care of the problem. These trucks are fairly forgiving in some ways but in others you do need to know what your doing or you WILL DAMAGE something Now you may have a very big expense on your hands!!

Good luck!

Thank you for the info. Yeah I just looked at it like any of the standard trucks I have worked on and found them. The fill for the transfer case was in an oddball location in my opinion but used a light to verify what it was before using. The from diff was milky so i flushed it with fresh gear oil before filling. The very rear diff was a metalic looking one. Gears and all felt fine and looking in looked alright but something (felt almost like a bolt or pin) was floating in the bottom so need to pull the top off of it and pull it all apart to check it out.Hi Jacob,

As far as finding the fill ports on the differentials and manual gear box - you could spend as much as a week rummaging the TM for location. My personal opinion is that who ever wrote them may never have actually even seen a MV! They are searchable as PDFs but you have to know the name of the thing you want more info about. That part can be pretty frustrating sometimes.

So, get yourself a big piece of cardboard or two and slide them under the truck. That will make it easy to slide in under and scoot around. Get comfortable. It should be relaxing to lay down there and look around. Grab a rag or two and bring your cell phone too - so you can snap pictures if you see anything that looks strange. We LOVE pictures!

Then, let's apply some logic to finding the oil level fill port (check port) problem:

1. You know for sure that the drain is on the very bottom. Gotta be that way so you can replace the oil when you get to that exercise.

2. The oil level can't be above the axles just because "that is how it is". Mostly because there is nothing but a little thin rubber seal at the end of each axle tube to keep the gear oil inside. So, around (generally just below center) you should see a plug that is about 3/4" in diameter. Some are bigger, some are smaller - but almost all will open with a half inch socket wrench on a Deuce or 5ton. Those that don't can be opened with a crescent wrench the first time - then get the right tool to put it back.

3. When you remove the plug, stick your finger in the open fill port, knuckle up and you should feel oil. It should smell like sulphur. Rub your fingers together. It should feel slick, not gritty and be dark in color. It if looks creamy and tan colored - you have water.

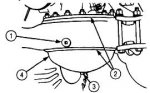

The picture below is a 5 Ton differential out of the TM. It is similar but different. Same rules apply to location and logic though. Gearboxes like your transmission (assuming it isn't an Allison Automatic) and transfer case can be inspected with the same logic.

Hope this helps and that it can be useful... #1 is fill/level and obviously #3 is drain.

View attachment 804444

Good Deal! The TMs definitely have a lot of info. When these trucks were on active duty, there were some parts "replaced as a unit". Out here "in the wild" that just means the training manual won't have any details about those "replaceable units". A good example is the rotation manifold on my wrecker... There is a picture of it in Dash 24, Book 3 but no details about the brushes that allow 24v power to pass through it to feed the spot lights.Thank you for the info. Yeah I just looked at it like any of the standard trucks I have worked on and found them. The fill for the transfer case was in an oddball location in my opinion but used a light to verify what it was before using. The from diff was milky so i flushed it with fresh gear oil before filling. The very rear diff was a metalic looking one. Gears and all felt fine and looking in looked alright but something (felt almost like a bolt or pin) was floating in the bottom so need to pull the top off of it and pull it all apart to check it out.

Makes sense about the replacement aspect. Like a buddy of mine working as a local fleet mechanic. He says if a part goes bad rather than service it he just replaces it. Where other mecbanics might service and rebuild. Just depends on the situation. Luckily from what I could tell (was hard as heck to get the metal off of transfer case and rear diff plugs) they are all magnetic. Also all of them where half inch drive plugs. Made it very easy.Good Deal! The TMs definitely have a lot of info. When these trucks were on active duty, there were some parts "replaced as a unit". Out here "in the wild" that just means the training manual won't have any details about those "replaceable units". A good example is the rotation manifold on my wrecker... There is a picture of it in Dash 24, Book 3 but no details about the brushes that allow 24v power to pass through it to feed the spot lights.

Another thing worth considering is adding a magnetic drain plug to all your axles. Transfer case too if you can... That way if something happens - and it isn't catastrophic - the bad stuff will show up on the plug possibly allowing you to catch it during yearly service. I have found parts of ring gear teeth on them before. Definitely not good, but the truck was still mobile enough to "make it back home" under its own power because the magnet caught the broken piece.

I checked the lo9-2320-209-12 (listed on my trucks dash) it is very in depth with grease points but after hours of checking and rechecking I never found the diff, transfer case, or transmission information aside from volumes.Reference post 88: The -20 manual is not the place to look for info on locations on drain/fill plugs or what product to put in. This information is located in the lubrication order which in he case of a deuce is LO9-2320-209-LO. Most of the check plugs are pipe ends and a 1/2" drive will open them. As the Army would not issue a drive set to every truck, in your OVM there was a piece of 1/2" square stock and an adjustable wrench with which you were supposed to use to check fluid levels. If you were short you had to draw the oil pump from the parts man to add the oil. There is a list in the appendix of the operators' manual that describes the tools authorized for the truck. The usability codes are used to sort out which items go with each model truck: some are all" others unique to 1 model such as a wrecker.

Get all the TM's for your truck in one place.I checked the lo9-2320-209-12 (listed on my trucks dash) it is very in depth with grease points but after hours of checking and rechecking I never found the diff, transfer case, or transmission information aside from volumes.

As for grease points I found the ujoints tend to suck if in the wrong position. My grease gun has a flex line but still couldn't get onto some of them at first.

I have printed and laminated that GTA for each of my trucks in the log book. It gives you a systematic pre-trip inspection of your vehicle and some pretty good hints of where to look for stuff!There is also really good PDF like GTA 9-1-1851-8 for you to work with