The parts for the secondary fuel filter finally showed up today, so I was able to go back to working on the 2006 unit. I know I need to pop the head on the 2007, but I'll save that work for a rainy day.

After getting the filter installed, I tried priming, but the fuel pump (old square style), just made a faint humming sound. Undid the suction side and tried blowing into the line going to the tank. Was completely clogged. Using compressed air, I cleared the blockage. While I had the line off, I dripped a little diesel into the inlet of the pump. It still just gave a faint hum. Tapped on the side of it, and little by little it got louder until all of a sudden it started pumping.

(This is a very well know problem. You have not fixed it. Just prolonged it to the day the lights go out. Get a new pump. )

I then reconnected the line from the tank and let it run for 5+ minutes to get the fuel circulate real good. I then tried to crank it. Nothing. I heard a click coming from the control box, but the main solenoid on the starter never engaged. Put a voltmeter on the solenoid and it never goes to 24V when trying to crank. Same deal using the dead crank switch.

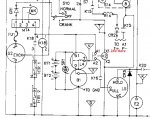

So I guess the relay that controls the starter solenoid needs to have its contacts cleaned? Need to study the starter circuit diagram to diagnose further.

( Apply 24VDC to wire # 114C on the S10-1. That goes right to the K2-X1. If the motor will not turn over, time to look at K2. Remove X1 & X2 wires from the K2 and apply 24VDC to those terminals. That way you have both + & -. )

Also also got in some fuel senders today. The 5.5" ones. Am I correct that it doesn't matter how I connect the red and black wires since it is just a resistor and the whole thing is floating being a plastic fuel tank? Or should I slip the one eyelet under one of the screws and tie the black wire from the sensor to it?